HOOD REMOVAL AND LINER REPAIR

The hood liner on

So I thought I'd post a few pics of the process for

my fellow newbies out there that want to repair the

liner on their hood. You can order the kit from Nicole's HookedOnCars

website. Other things I used include:

Odorless Mineral Spirits (for cleaning the old residue off the hood)

Distilled water in a spray bottle

3M Spray adhesive #80

Wax Paper

Painters Masking Tape

Newspaper

Squeegee

Towels

Tape Measure

Tools needed are:

A 13mm socket, ratchet, 3" extension bar,

Stiff nylon brush (1 wide one, 1 narrow one)

Large drywall taping knife.

First, remove the hood. Removing the hood is easier with 2 people but can be

done with one which is what I did here. First, remove the wiper motor and

blower motor cover by lifting up on the rubber trim side to separate it from

the firewall and pull forward.

Follow the electrical wiring from the hood and disconnect the 3-pin and 2-pin

electrical connectors - one wire on each side of the hood.

You may have to "un-route" the driver's side electrical wire from

under the A/C lines so it is free to move with the hood.

Next, disconnect the two wiper washer fluid supply lines. On mine, one

connection was external to the cover plug and the other was internal. Mark one

of the lines with tape to indicate whether it was the internal or external

connected line so you can connect it back the same way on install.

It is best to mark or photograph the orientation of the hood bracket to the

hood before disassembly so you can install the hood "in the

neighborhood" of where it was originally on install and fine tune from

there. Also, don't wash the area around the hood bracket when you have it off.

Sometimes the dirt lines will outline the location of othe

bracket for you when your ready to install.

Next, detach the hood shocks. You can use a small screwdriver or a pick tool to

pry the spring clamp away from the shock mount. With the clamp pulled away....

...pull the shock away from the hood. Do the same for the other side but be

prepared to support the weight of the hood after you disconnect the last shock.

Next, support the hood with a 3'-4' rod or pole

Finally, use a 13mm socket to remove the 4 hood bolts

(2 each side). My hood had spacers between the bracket and hood so be prepared

to catch those when you remove the bolts. If you're doing this by yourself, I

place towels between the hood and exposed fender locations such as near the

windshield and at the front hood latch so as not to scratch any body paint. You

will need to support the hood with one hand while removing the last bolts with

the other.

The hood is not heavy and can easily be handled by one person. When you have it

removed, find an open area to work in and place a blanket or soft material

underneath the hood to protect it from scratches.

I used a drywall taping knife to scrape the old liner off the hood. Don't worry

about trying to scrape it completely off the metal because the old adhesive is

usually alive and well underneath and will require a solvent to get off without

scratching the paint.

Once you've scraped the old loose material off, it should look something like

this. It's best to remove this material as well in order to get good contact

for the new material and adhesive.

I have found Odorless Mineral Spirits to work very effectively at removing the

old adhesive.

Pour enough mineral spirits (or other solvents you may have good luck with) on

the old liner material to generously soak the material but not pool in the

center of the hood.

Use protective gloves to spread the solvent around the hood evenly.

I used a stiff nylon brush to remove the old adhesive and liner off the hood. The stiffer the better. The old material tends to ball up

like little balls of rubber cement.

I used a stiff narrow nylon brush to get at the material under the hood liner

lip as shown.

You can use a heavy duty shop vac to vacuum up the

loose particles that come off during the process.

After the vacuum, use a rag to wipe off the remaining debris from the hood so

that there is none remaining.

The mineral spirits leaves an oily residue that needs to come off before new

adhesive can be applied. I use a degreaser such as Orange Blast. Spray the

degreaser on the hood surface as shown.

And wipe off with a clean rag.

Next, dry fit the new hood liner to ensure it fits properly. It's also a good

idea to test fit so you know how tight the side and top margins are for when

you install it - this will give you some idea how to position it for

installation with adhesive applied.

After the test fit, you will need to mask off all of the

underside of the hood except the area that is to receive the adhesive and

liner. Use painters masking tape and newspaper and

mask the hood as shown.

The instructions that came with Nicole's kit recommend 3M #80 Rubber and Vinyl adhesive. I found mine at HD.

You can flip the liner over so the back is exposed and lay

it on the hood as shown. Then spray the backing with a moderate coat of the

adhesive.

Move the liner to a clean workspace and then spray the hood surface with a

moderate amount of adhesive as well.

Use wax paper to provide a protective, non-stick layer between the hood and the

new foam liner.

It took 3 strips of wax paper to cover the whole hood.

Position the new foam liner with adhesive side down on top of the wax paper.

Position it so that there is equal margin of foam liner all around the edge of

the hood. With the wax paper underneath, the liner will not fit under the hood

lip just yet.

Next, begin removing the wax paper. Start with one of the outer strips and pull

it out toward the side of the hood as shown. Hold the hood liner in place with

one hand over the remaining wax paper areas while pulling out the strip of wax

paper.

Next, pull out the middle strip of wax paper by pulling it out one end of the

liner as shown. Again, hold the liner in place with one hand while pulling the

wax paper out with the other.

As you remove the wax paper, also remove the newspaper and masking tape and

allow the liner to fit under the hood lip.

When all the wax paper has been removed and the newspaper and masking tape as

well, press the liner down on the hood over the entire surface with your hands

to ensure the whole surface area is "glued" down.

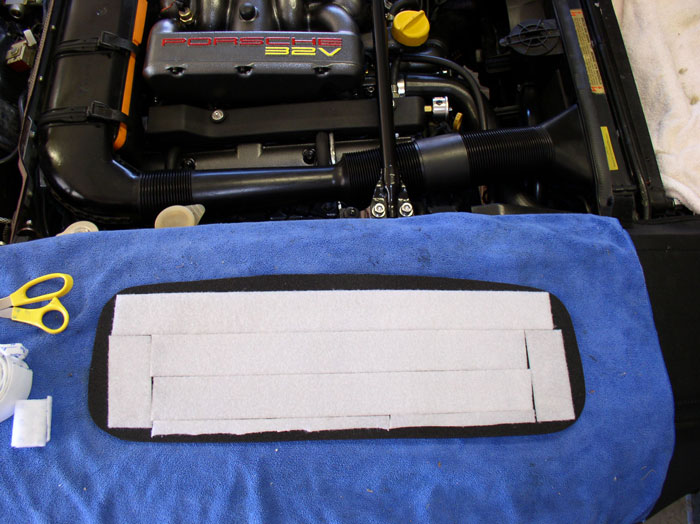

The liner kit also came with a smaller piece that fits on the front of the

hood. Since the front of the hood has a nice emissions sticker that I did not

want to cover up permanently, I decided to experiment with a temporary solution

- industrial strength Velcro. I cut strips of heavy duty Velcro and attached

them to the back side of the small liner as shown. Use the "soft"

side of the Velcro to attach to the foam liner and the "hard" side of

the Velcro to the hood.

For the hood, I thought I'd try small squares of Velcro at first to see how

they held up. I wanted it to come off easy enough so didn't cover the entire

area with the "hard" side of the Velcro.

Position the small liner over the hood and attach.

Smooth out the surface with your hand to make sure all the Velcro makes

contact. At first, it looked great (see below). However, after a few weeks of

hanging upside down under the hood with engine heat applied, I noticed the

liner wasn't laying flat against the hood any longer so I will have to

readdress this with more Velcro soon and see if it takes care of the

problem.† In the end, I decided to remove

the smaller pad and leave the paint and emissions sticker exposed.† I liked this idea better than adding more Velcro.† Itís a matter of personal preference and the

condition of the underside of the hood.

At this time, you're ready to install the decal. However, I did not have the

decal at the time and I needed to install the hood. The decal can be installed

while the hood is on the car and that process will be demonstrated here. So,

you can jump ahead and follow the decal procedure then jump back here to

install the hood. To install the hood, first, lubricate the hinge joints. I

used a light general purpose oil. Work the hinges up

and down several times to work in the oil.

If you're working alone, like me, lay out your bolts and shims and wrenches so

they are easily accessible near the hinges. I had two shims for each side.

Place a towel under the hood near the hinge and cowl to protect it from

scratches. I also left the service covers on for fender protection. Bring the

hood over and gently lay it into position as shown.

Next, lift up one side of the hood at the hinge and insert the shims. Line up

the holes for the front bolt and install the 13mm bolt - I used the 13mm socket

and 3" extension bar. Do the same for the other side of the hood.

I then lifted the hood with one hand and used the other to start the rear bolt

using the extension again. The objective is to simply get the bolt well started

in the hole. Do the same for the other side of the hood.

Next, support the hood with a wooden or rubber tipped rod. I used a clothes

hangar dowel you find in your closet. Remove the service covers at this time so

you can check for proper alignment.

Now you can fine tune the adjustment. First position the hinge so that it is

approximately where it was when you removed it. I was careful not to wash or

wax the area at the hinge since the original 'dirt' left a marker where the

hinge should go.

When it's lined up as close as you can get it to it original position, snug all

four of the bolts down LIGHTLY - just enough to hold them in place as you make

final adjustments.

Move to the front of the hood and check the alignment of the hood pin to the

receiver latch. It should be perfectly centered in the hole. Mine was very

close on first try but I had to fine tune it. Do not try to latch the hood

(i.e., press it all the way down into the receiver) unless it looks perfectly

centered - otherwise it can get wedged in there and be difficult to

"unlatch". If it's not lined up perfectly, raise and support the hood

enough to gain access to the bolts at the hinges and loosen enough to adjust

the hood slightly. For example, when looking at the hood from the front of the

car, my hood pin was a little to the left of the center of the receiver hole. I

loosened the passenger side bolts at the hinge and moved the hood forward about

1/16 of an inch then snugged the bolts down again.

Then go to the pin and receiver at the front and check alignment again. It took

me two adjustments to get it centered. It's trial and

error mixed with a little patience and you can get it perfect. When it's

aligned in the center of the receiver, close the hood all the way and try

opening it from the hood release lever in the car to check for normal

operation. I have found this method also ensures the gaps between the hood and

fender consistently come out even as well. The final adjustment check to make

is hood height. It should be flush with the fenders. If it's too high or low,

you will need to make an adjustment at the hinge again. This time, when you loosen

the bolts, simply raise or lower the hood a the hinge to get the right height -

trick is to keep the bolts snug enough that you can move the hood at the hinge

without allowing it to slip forward or back. After the height adjustment, check

for normal operation again.

When the hood operation check out, torque the 13mm hood

bolts to 15 ftlbs.

Next, make the electrical connections. There should be a 2 pin connector and a

3 pin connector to the hood. These are for the heated windshield washer nozzles

and hood light. Make both of these connections as shown.

Next comes the windshield washer fluid hose

connections. When I removed the hoses, you may remember that I marked (taped)

one of the hoses with "external" because one of the hoses was

connected external to the hood and the other hose was connected internally.

First, connect the internal hose fitting. On mine, it was located up inside the

hood. After locating it.....

....push it down through the hole in the plastic cover plate and connect the

"internal" hose.

Then, connect the "external" hose to the other external fitting.

Fit the plastic cover over the hole in the hood and push it in until it snaps

into place. Bundle the wire and hoses together with a plastic bungee or zip

tie.

Now you can install the wiper motor and fan blower motor cover. Place the cover

into position, guiding the hood wires at each end into their recessed openings.

There are two tabs that hold the rear edge of the cover in place. They are

located just under the cowl. Ensure the rear edge of the plastic cover fits on

top of these tabs and slides under the cowl. See pic

below where tab is at the end of my finger. I needed to pry one of my tabs open

slightly as it looked like it was too tight to allow the cover to slip in.

Next, press the front of the cover down over the firewall top edge.

Attach the bottom of the hood shock to the ball connector as shown. These

connections simply "snap" on without the use of a tool.

Attach the top of the hood shock to the ball connector on the hood as shown.

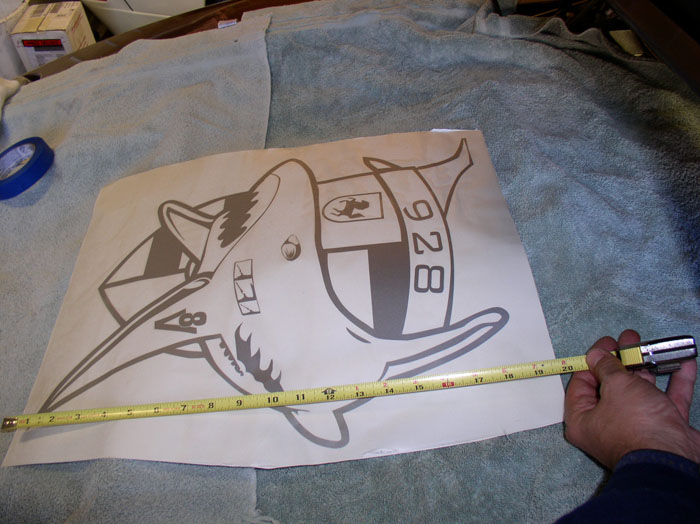

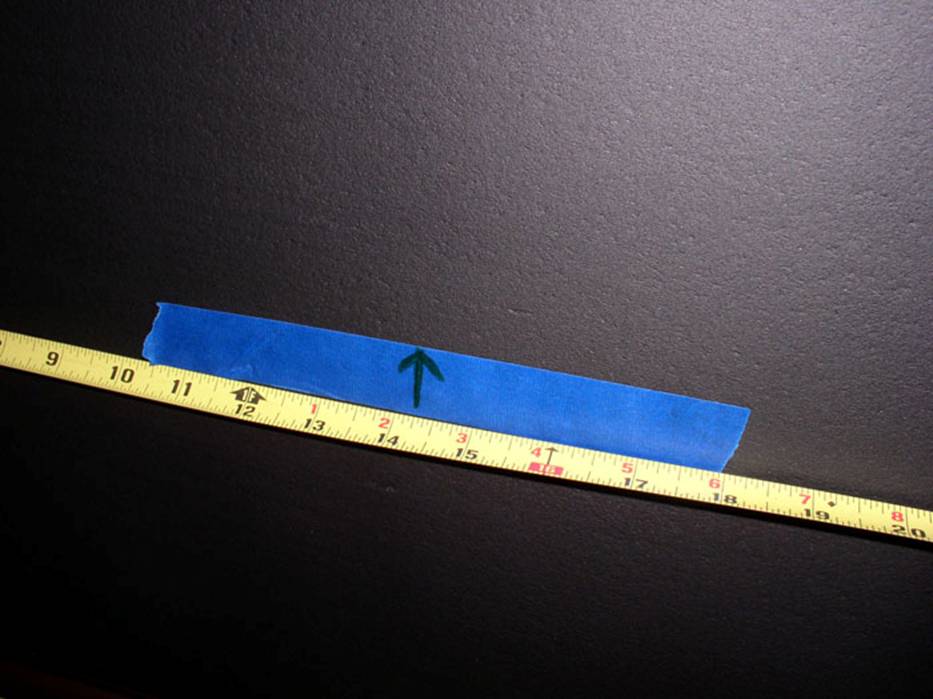

To install the decal while the hood is on the car, lay out towels across the

engine bay. Then lay out the decal.

Measure the decal height. This one is about 20".

Since I wanted the decal to be approximately centered vertically on the hood, that left about 6 inches of margin at the top and 6

inches at the bottom. Measure about 6 inches from the top of the hood liner and

place a piece of painter masking tape across the hood as shown (centered

approximately horizontally on the hood pad) - ensure the tape is level by

making sure each end of the tape is also 6 inches from the top of the liner.

Perform the same operation on the bottom of the hood - about 6 inches up from

the bottom of the liner place another piece of masking tape.

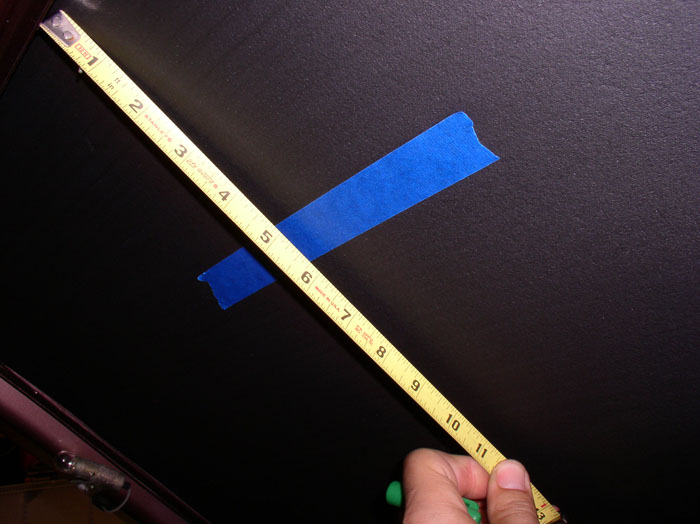

To center the decal horizontally on the hood, you will need to mark the center

of the hood with a mark on the tape. the center of the

upper part of the hood is approximately 13.5 inches. Measure 13.5 inches from

one edge of the liner to the masking tape and mark the center with a line as

shown.

The center point near the bottom of the hood is approximately 14.25"

inches. Measure from the edge of the liner to the masking tape and mark

accordingly.

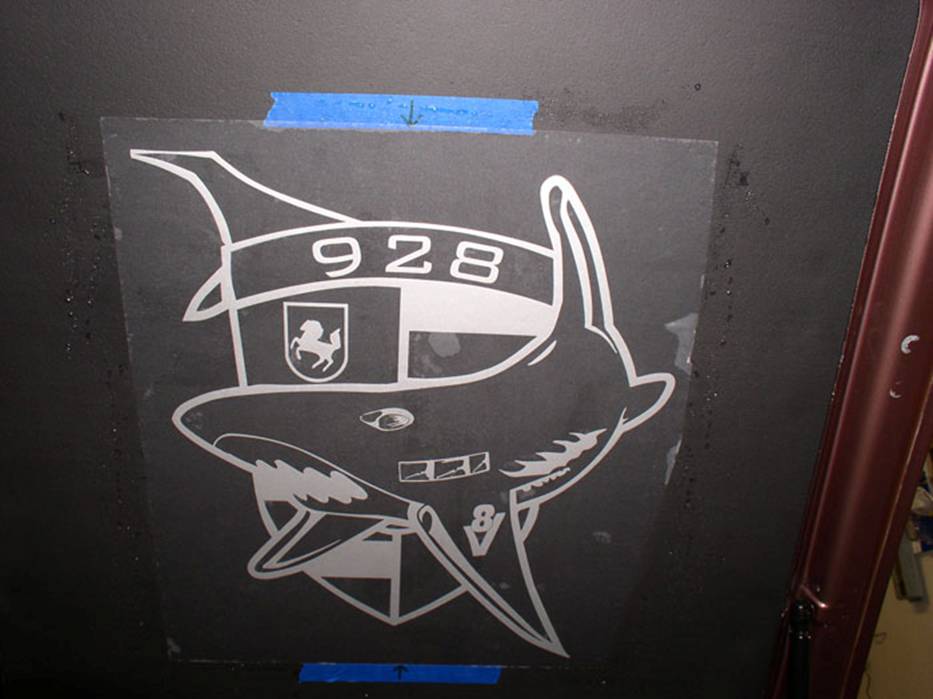

The tape and center markings should look like this. I used the number

"2" in "928" at the top of the decal as the center point to

line up with the arrow on the upper piece of tape and I used the pointy end of

the shield at the bottom of the decal to line up with the arrow on the bottom

piece of tape.

Next, I used distilled water in a spray bottle to spray a light amount of water

on the hood liner across the area where the decal would go.

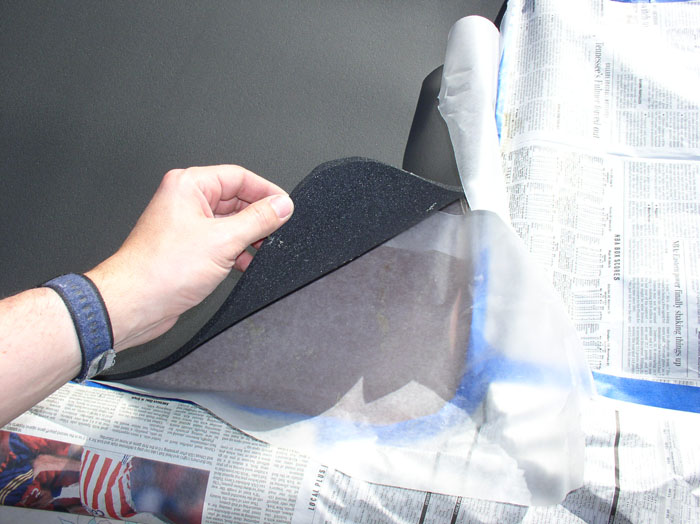

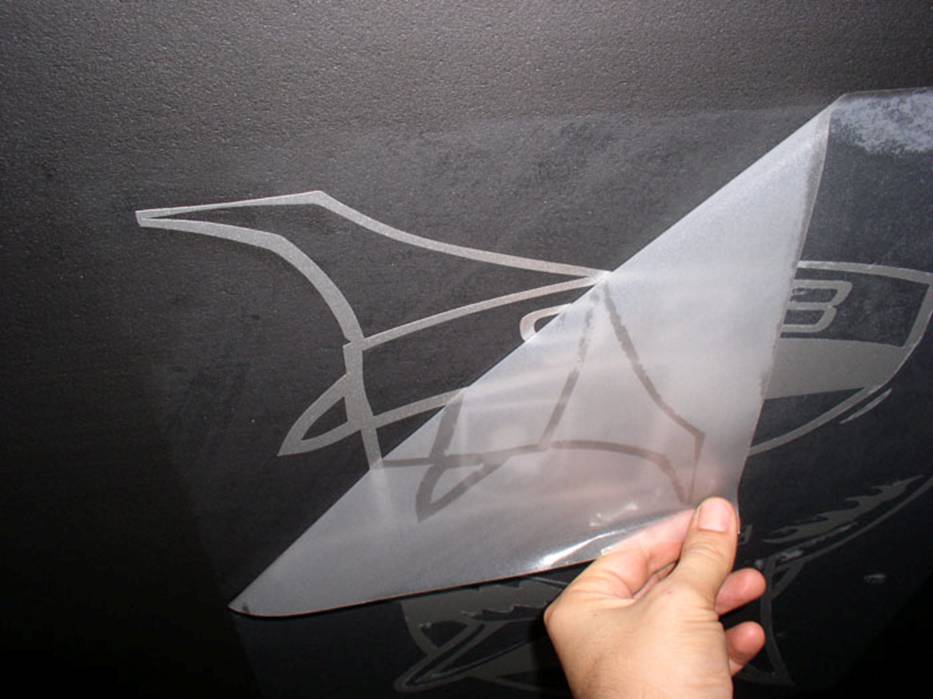

Then, remove the protective backing from the decal as shown. Be sure to pull

the backing away in a parallel fashion rather than straight up. This will help

keep the decal attached to the film underneath.

Next, spray the decal surface with a light amount of water.

Then, position the decal so the "2" and the pointy end of the shield

line up with the arrows on the tape. Smooth out the decal so that it sticks to

the liner.

Once your happy with the position of the decal, use a

squeegee to press out the air bubbles and excess water behind the decal.

When done with the squeegee, it should look something like this.

Wipe the excess water from the liner and decal with a clean towel.

After the decal has had time to dry (I waited about 30 minutes but you could

wait longer), you can begin peeling the protective layer off. Keep the peeled

material as close to the liner as possible while peeling. If you peel it off straight

up, you may dislodge the decal that remains behind. Take it slow and careful.

See below.

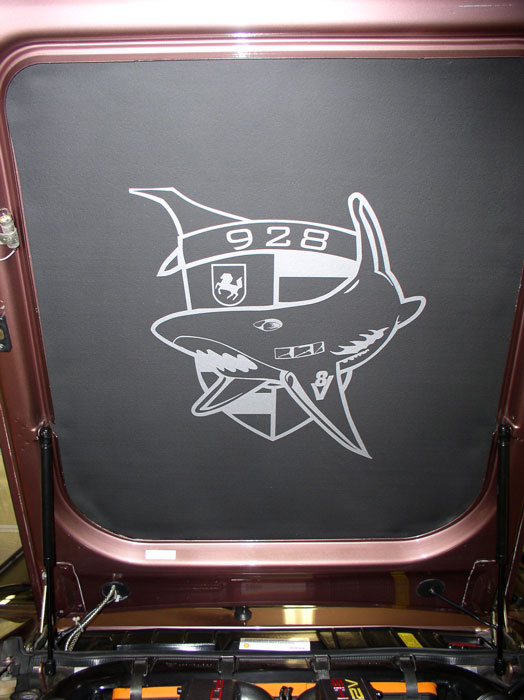

After you removed the protective film, use you finger to "squeegee"

the remaining water out from under the decal material and ensure it is smooth.

Dry off the excess water with a towel. Your installed decal should look

something like this.

Congratulations - You're done!!

Please feel free to comment or recommend tips/improvements to this thread - I'm

always interested in improving the quality of these threads. I'd also like to

thank Nicole for a great product - THANK YOU! ![]()

THANKS for reading!