88 Fuel Sender Seal Replacement w/pics

A

while back we noticed the smell of fuel coming from the rear of the '88 after

we filled it up. I couldn't find any fuel leaking on the ground but there was

definitely a strong fuel smell coming from the rear. I opened the hatch, looked

under the carpet and opened the cover over the fuel sending unit. There was

fuel standing in the depression all around the top of the fuel sending unit!

Apparently the seal was ruptured or had failed.

We drove the car enough to get the fuel level down and it stopped leaking. I

ordered a new seal (about $3 at 928 Intl) and just this weekend decided to

replace the seal. For other noobies like myself, I've

include a few pics of the procedure. I'm still trying

to figure out the photo software I'm using on my computer and the pictures are

smaller than I'm used to with my old software. Hopefully, they are large enough

to make sense.

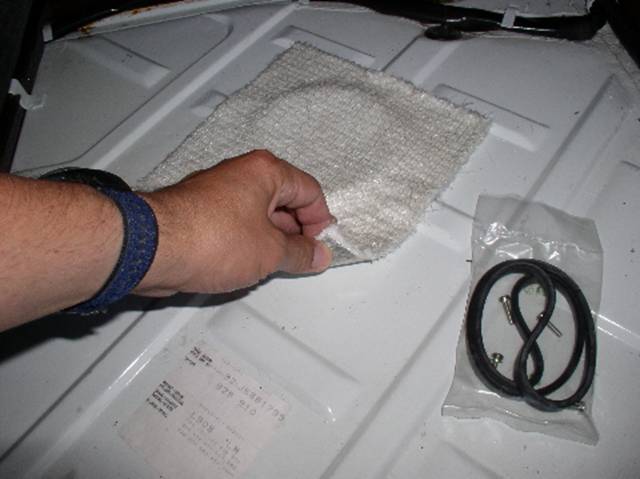

Under the rear hatch carpet you'll find a square fabric pad that is attached to

the floor with adhesive. Just peel it away.

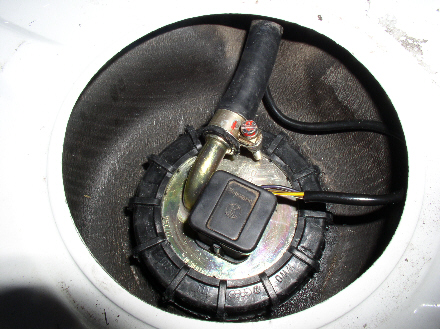

Underneath the fabric, you'll find a round black plastic cover. This fits

snugly on a lip. Get your finder under the lip (or use a flat blade screwdriver)

and pull the plastic cover off.

Underneath, you will see the fuel return hose and the electrical connector to

the fuel sender unit.

At this point, if you are not going to be testing the electrical connections,

it is wise to disconnect the battery. In my case, I wanted to check voltages

coming into the sender and return voltages coming out so I left the battery

connected. Just be very carefull not to create any

sparks while testing the electrics! The electrical connector simply pulls off.

Pull straight up while rocking side to side.

Next, you can open the connector housing by using a flat blade screwdriver to

pry one of the side tabs open and pull the top off the connector.

With the top off the connector, you can see the wires coming into the sender

unit. The brown wire is ground. The purple wire is the voltage that indicates

fuel level while the yellow wire is battery voltage and is used to indicate

when fuel is so low (reserve) that the low fuel light will come on.

I checked the voltage coming to the sending unit by connecting the voltmeter to

the gound and the purple wire while the wires were

disconnected from the sender unit. You have to turn the ignition switch on to

get the voltage - you do not need to start the car. I receive 5.35V at the

sender. When I tested the '84, I received 5.25V at the sender.

Next, I checked the yellow wire and ground and received battery voltage while

the ignition switch is still on.

Next, I reconnected the wires to the sender unit without the connector housing

so I could check the voltage coming back from the sender. It should be a

smaller voltage than coming in depending on the fuel level. I got 1.917V while

the tank was just below 1/2 full.

At this point, turn the ignition switch off and disconnect the battery if not

done so already. Reassemble the electrical connector in the same order as they

came out and snap the top on the connector into place. Then using a flat blade

screwdriver, loosen the clamp on the fuel return hose and disconnect. You may

want to place a towel around the area to soak up any dripping fuel - the hose

is not under pressure but may have some fuel still in it.

Now you can remove the ring nut. I used a large pair of oil filter pliers. Mine

was on pretty tight so get a good grip with the tool so you don't damage the

ring nut too much - it's just plastic.

Once the ring nut is loose, remove it from the sender unit.

Now you can lift the sender unit out. Lift straight up but don't remove it from

the tank. It will be filled with fuel so lift it high enough to let it drain

out first then with it almost out of the tank, tilt it slightly side ways to

drain what's left in the bottom cup out. Then remove the sender unit.

With the sending unit out, you can remove the old seal.

I compared the old seal to the new and it was obvious why the tank was leaking

when filled. Parts of the old seal were deformed around the perimeter of the

sending unit.

With the sending unit out, just for fun, I checked the resistance of the unit

by connecting the multi-meter (set for ohms) to the ground and fuel level pins

(where the purple wire goes and the brown ground wire goes). Holding the

sending unit upright, the float will sink to the bottom (you should hear it

fall). This simulates a completely empty tank. I got 70.5 ohms resistance.

Then I turned the sending unit upside down and the float falls to the top

(simulating a full tank) and I got 5 ohms. So in theory, when the tank is full,

the voltage being returned from the sending unit should be close to the same

voltage coming in (i.e., 5.35V minus about 5 ohms resistance). A low voltage

should be returned (less than 1V) when the tank is empty or near empty.

Next, you can start putting it back together. First, place the new seal over

the top of the sending unit.....

....and ensure it is seated properly all around.

Carefully lower the sending unit back into the tank. You will need to feel or

search around for the unit to go into the holder at the bottom of the tank. In

other words, there's a plastic hood at the bottom of the tank with a round hole

in the top of it that the sender unit fits down into. Once you get it, you can

seat the unit to the top of the tank. Then place the plastic ring nut back on

the sending unit and tighten back down. Make sure the return hose pipe fitting

is oriented to (facing) the rubber hose before tightening the ring. Next, you

can fit the hose back onto the return fitting. It's a cramped fit but you can

bend the hose to get it on - then tighten the clamp with the clamp oriented the

same as it came off. Finally, place the electrical connector back on securely

then reconnect the battery.

At this point, you can fill it up with fuel and check for leaks. I filled it up

and let the car sit over night with a completely filled tank and checked for

leaks the next day. Dry as a bone! After ensuring there are no leakes, you can put the black platic

cover back on, place the adhesive fabric in place and place the carpet back in

place. You're done!

Feel free to comment or recommend improvements to this procedure. THANKS for

reading!