Instrument

Cluster Repair w/pics (Part II)

I

had been experiencing problems with my fuel gauge not registering full when I

filled up (only 3/4) and my speedometer started malfunctioning (only worked

when the sun heated up the pod). After a lot of troubleshooting to narrow it

down to the instrument cluster, I decided to remove the pod (for the first

time) and try cleaning the connections on the instrument cluster.

Here's the list of tools I used to work on the instrument cluster:

1) Standard (flat blade) screwdriver

2) Phillips screwdriver

3) 7mm Nut Driver

4) Pliers

5) Soldering Iron and Electrical Solder

6) Electronics Cleaner and Q-Tips

7) Pink Eraser

8) Ohm Meter

9) Selectable AC to DC converter

10) Small Flexible Snake Light (optional for viewing instrument warning lights)

I've included a few pictures for others (like myself) that have never done this

before - so this is a Noobie-rated procedure. ![]()

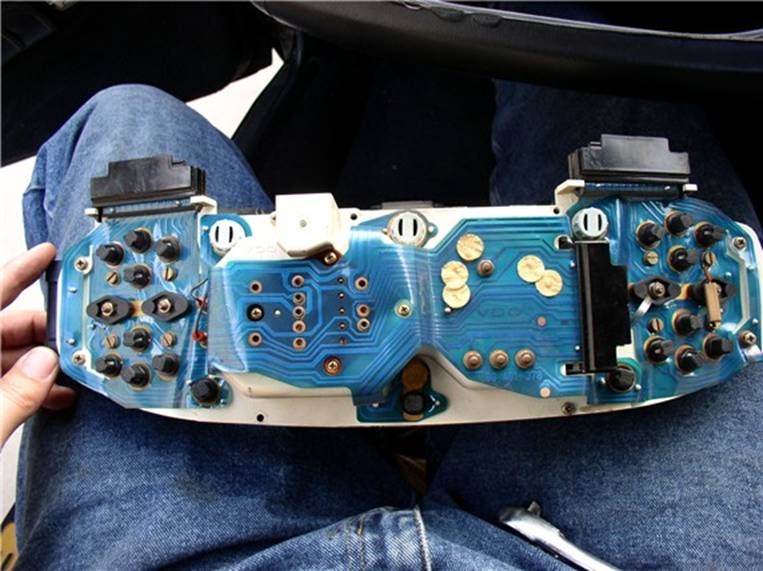

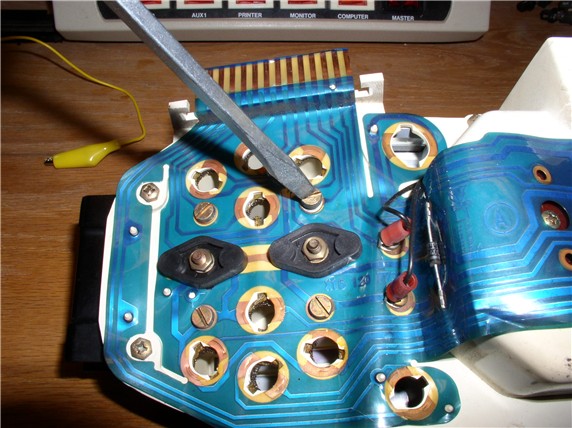

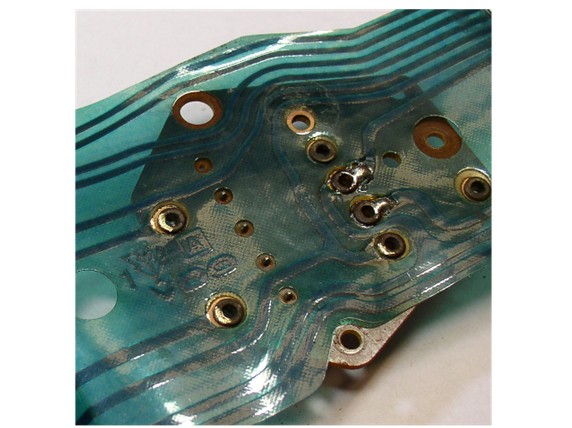

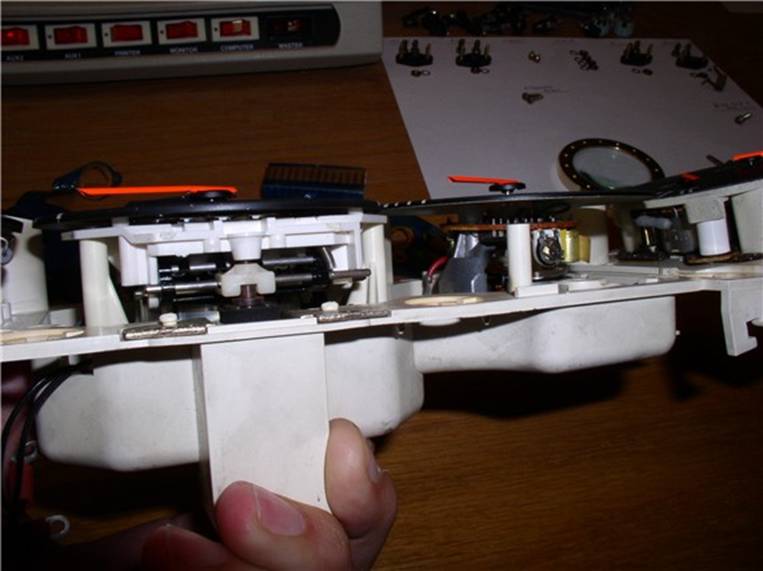

Here's the instrument cluster once it's been separated from the pod. This is

for the 1984.

Here's where the right-hand instruments are located looking at the back side.

There was a 68 Ohm resistor over the alternator/batt

gauge.

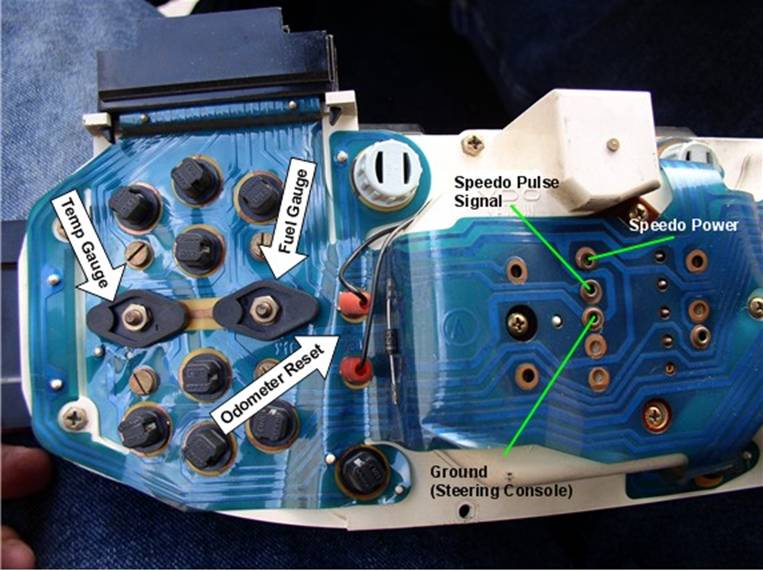

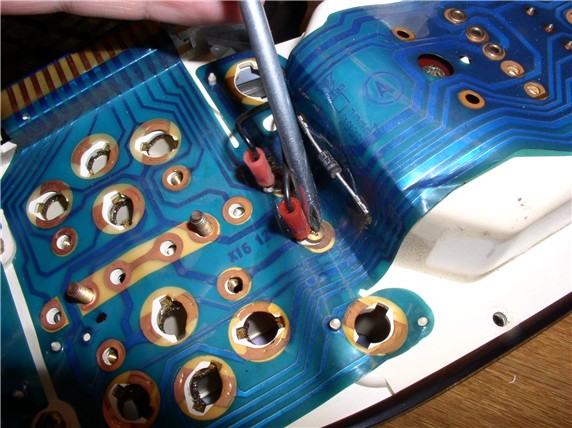

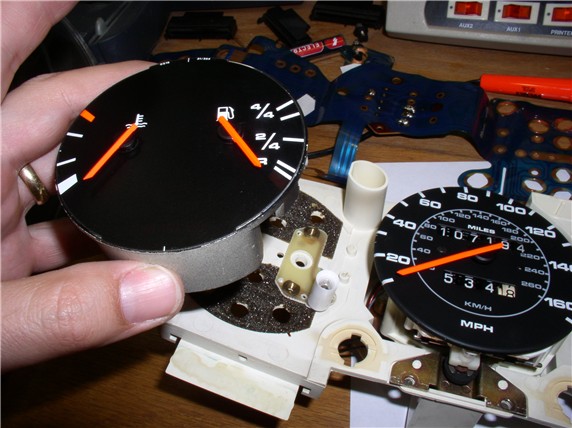

On the left-hand side were the two problem areas for me: Fuel and Speedometer.

So I mapped which signals were coming into the speedometer at the identified

rivets at the back of the speedo. The two red

connectors with wires attached that run under the speedo

cover are for speedometer reset.

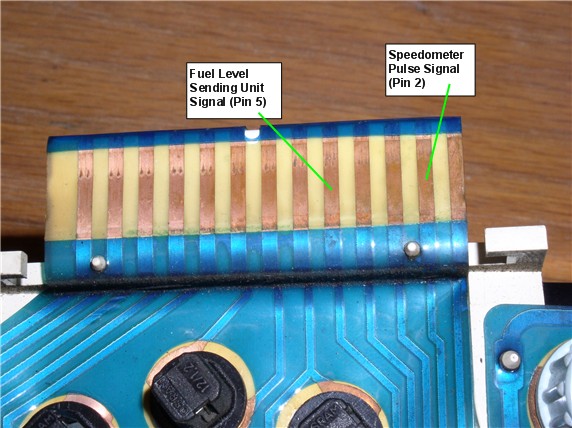

The Fuel level sending unit signal and speedometer pulse signals arrive through

pins 5 and 2, respectively on the left-hand wiring harness connector. I found

this by tracing the wiring diagrams that I got with Jim Morehouse's

CD of Technical Treasures - GREAT reference! ![]()

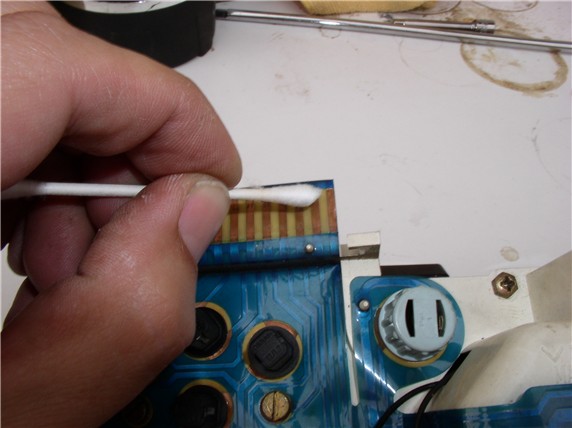

I planned to simply clean all the connectors first and test to see if I got any

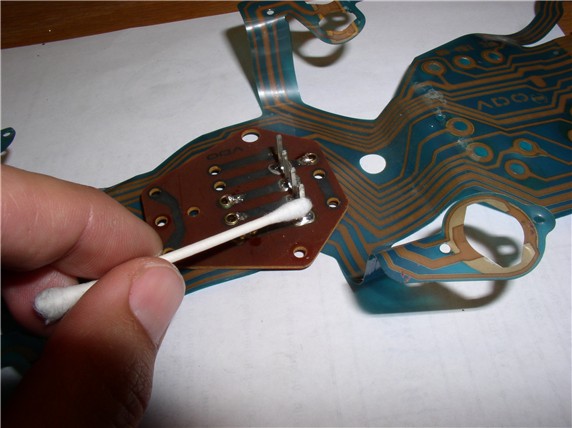

improvement. I've been using the CRC Electronics Cleaner.

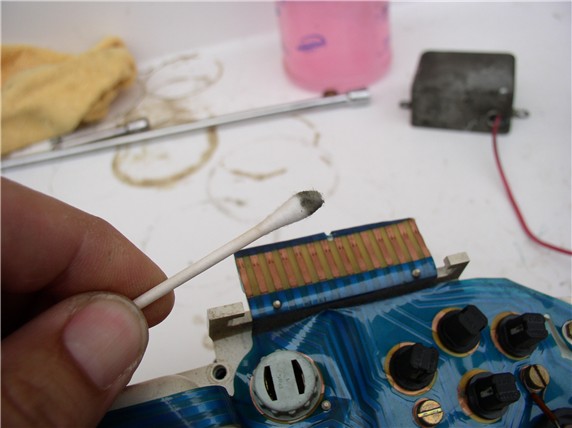

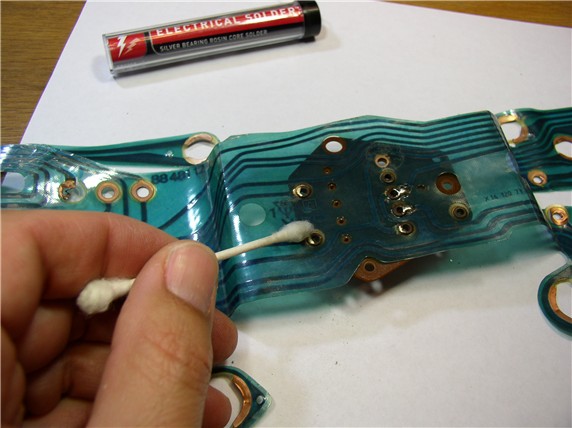

In order to get a good cleaning, I used q-tips (soaked in the CRC cleaner) to

clean the connectors....

On some pins, I got a light greenish residue...

On some other pins, I got a black residue....

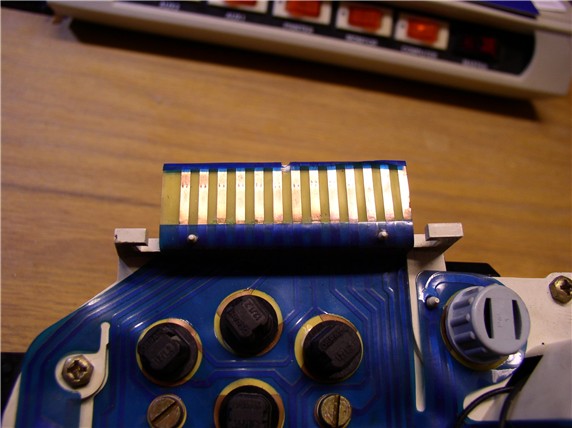

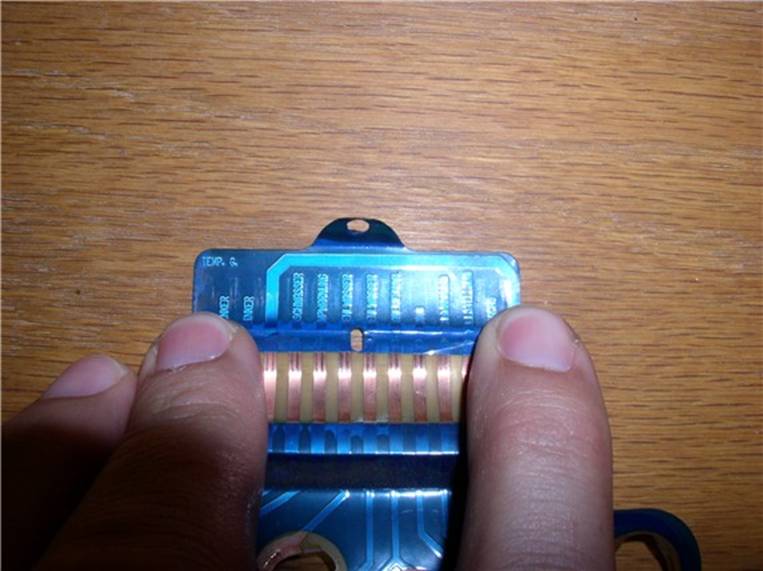

Even after the cleaning with the CRC and Q-tips, the connectors didn't look

very clean. So I decided to use a pink eraser. The trick here is to hold the

plastic circuit board firmly in place with your fingers while using the eraser

so as not to wrinkle or crease the plastic.

After the eraser cleaning, the contacts looked a lot cleaner.

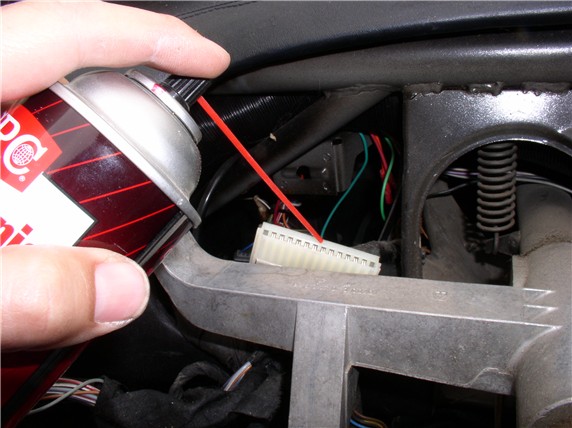

I then went to the harness and inspected the connectors there and sprayed with

the CRC as well. These connectors all looked very clean to begin with.

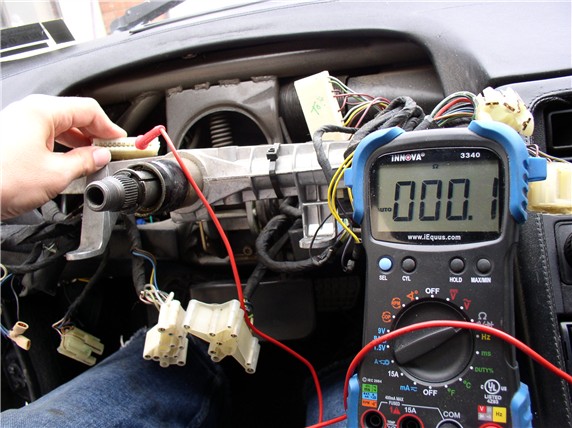

Finally, I checked the wiring harness end-to-CEB connections for continuity and

got something like 0.1 ohms. I even tried jostling the wires while checking to

see if there were any intermittent problems. Everything checked out fine.

At this point, I put the instrumentation cluster back into the car (without the

pod) and connected up the 3 wiring harness connectors. Then reconnected the

battery and started the car. BTW, I had filled the fuel tank to capacity before

starting this repair so I expected the fuel gauge to register full if

everything was functioning properly.

I seemed to actually see some slight improvement in the fuel gauge - it showed

a little above the 3/4 but not at full. I also drove the car and the

speedometer showed no improvement - still would not function. However, I

noticed that with the back of the instrument cluster

exposed, I could lightly touch the connections (rivets) at the back of the

speedometer and when I did, the speedometer acted erratically - doing all sorts

of funky things.

So, it looked like I would have to go further with the repair and do some

soldering. I parked the car, disconnected everything and brought the cluster in

the house for disassembly.

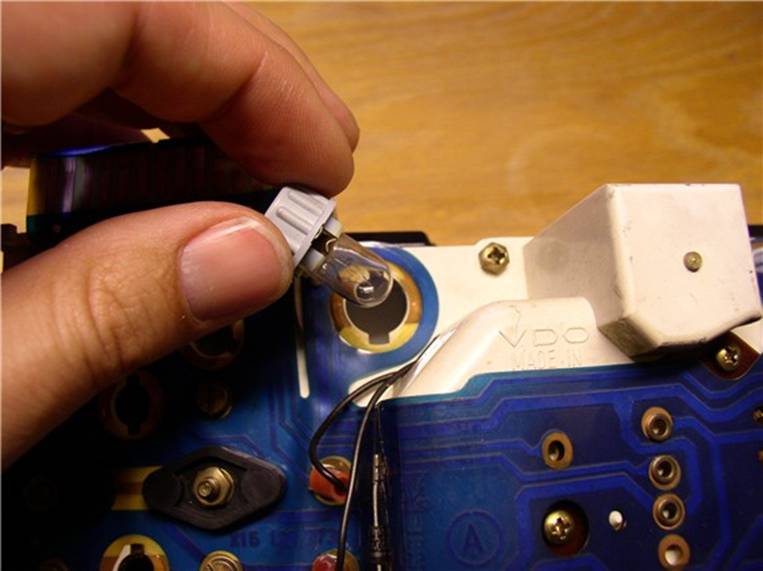

In order to remove the

plastic laminated circuit board, first remove the bulbs. There were two types of bulbs - the indicator/warning bulbs (black plastic) and the instrument illumination bulbs

(grey plastic). The indicator/warning bulbs

are removed by twisting counterclockwise 90 degrees and lifting up.

The instrument illumination bulbs are removed in the same manner -

there were three of these.

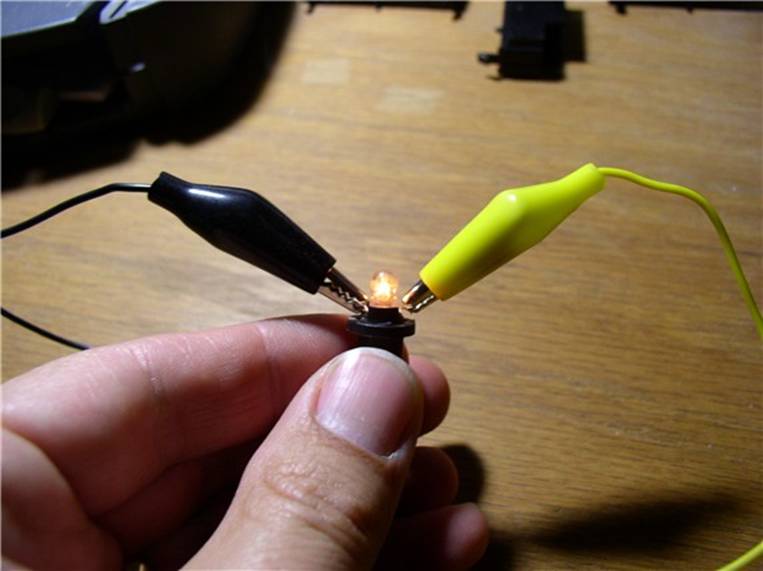

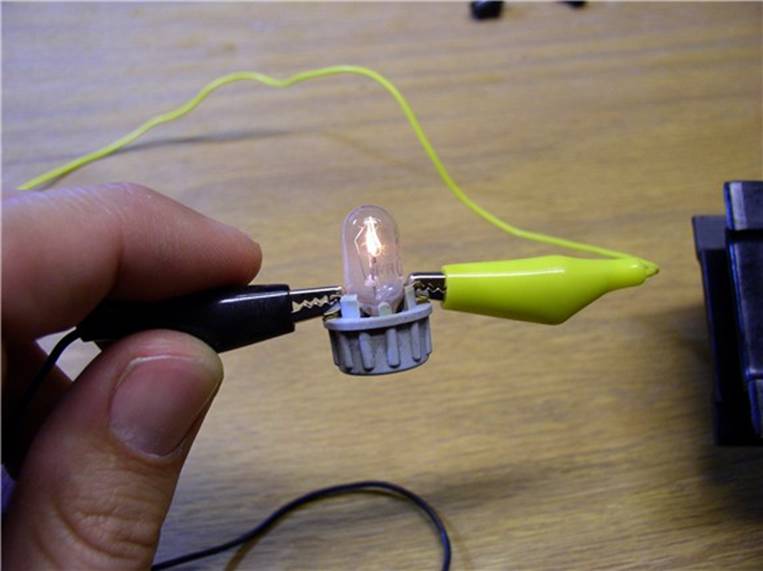

Once you get the bulbs out, it's

a good idea to test each one to see if it is working properly. I used an AC/DC

converter that had selectable output DC voltages. I set it to 9 Volts and

connected the power leads to the bulb connections on opposite sides. After

checking all the indicator/warning bulbs,

I found I had one that was burnt out and another that was very dim - So I

ordered a couple of replacements from 928 Intl.

I checked the illumination bulbs

as well and all three checked out. However, new replacement bulbs for these were only $1 each, so

I went ahead and replaced them with new and kept the old for replacements.

Just for fun, when you get the bulbs

out, you can use a thin snake light to illuminate each of the indicator/warning

cavities and see what warnings you've got but maybe never seen before.

Here's a signal indicator I've never seen illuminated before. Turns out it

seems to be for a trailer turn signal contact when towing something (according

to the wiring diagram).

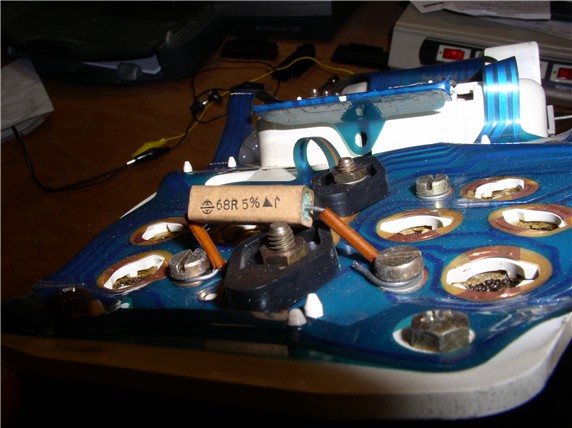

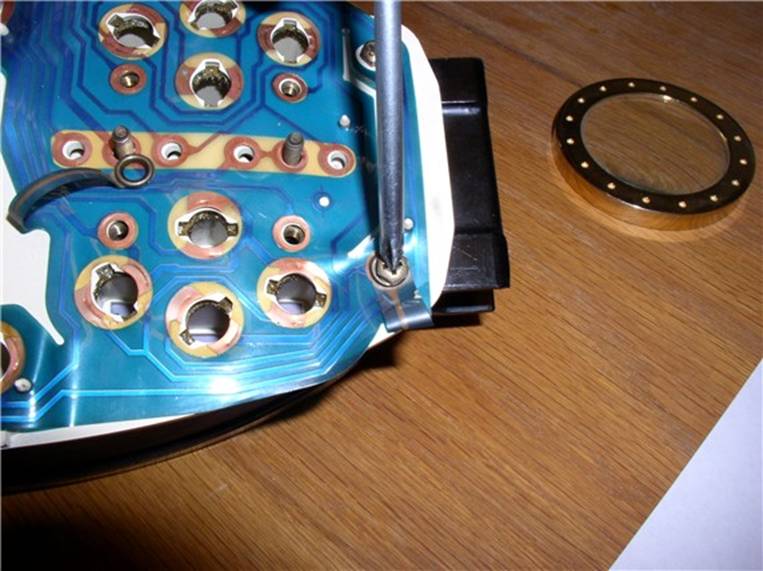

Next, remove the standard flat blade screws. There are two for each of the four

gauges and each screw has a small washer.

There is a 68-Ohm resistor attached to the screws by the Alternator/Batt gauge on my '84. The washers were located underneath

the resistor wires.

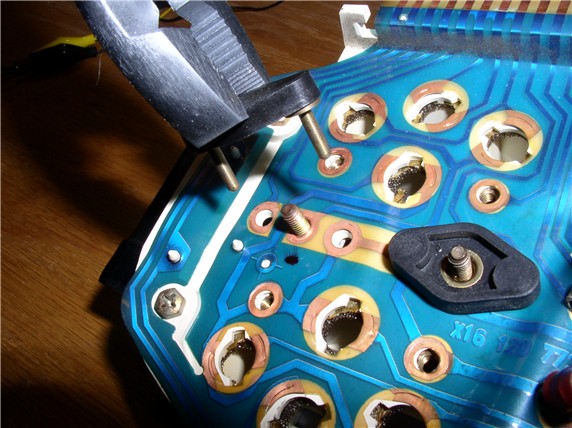

Then remove each of the 7mm nuts that hold the gauges in place and connected to

the instrument cluster

enclosure.

Once the nuts and small washers are off, you can use a pair of pliers to

carefully grab the sides of the plastic diamond-shaped connector and work it

back and forth while pulling up.

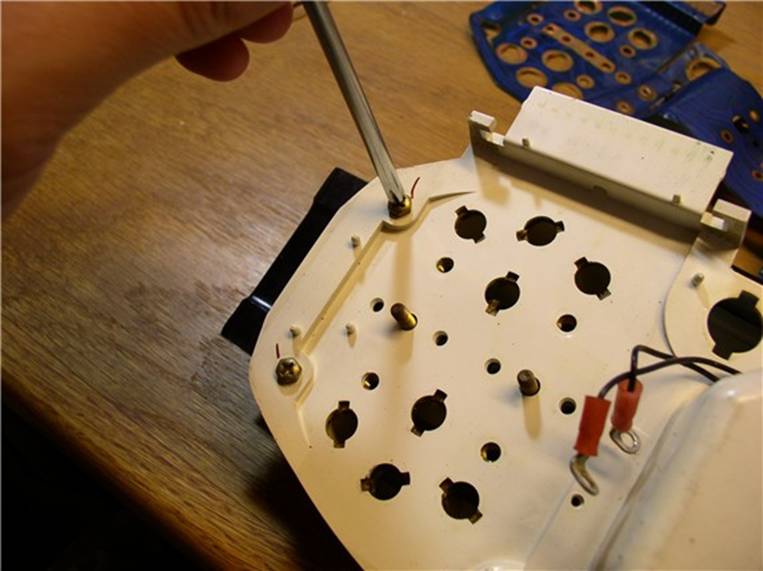

Next, you can remove the 7mm nuts that hold the tachometer in place - there are

four of these (also with washers).

The odometer reset screws are next. They take a phillips screwdriver. I had to slightly bend flat the

connectors in order to get the phillips

screwdriver in place. It's a good idea to mark one of the connection wires in

case they get mixed up. I marked the top wire at the red plastic casing with a

"T" using a sharpie.

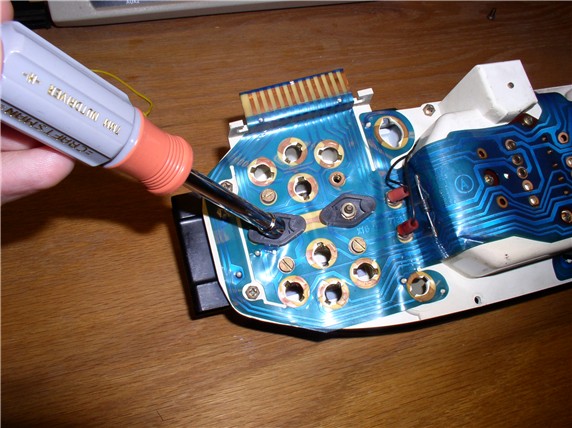

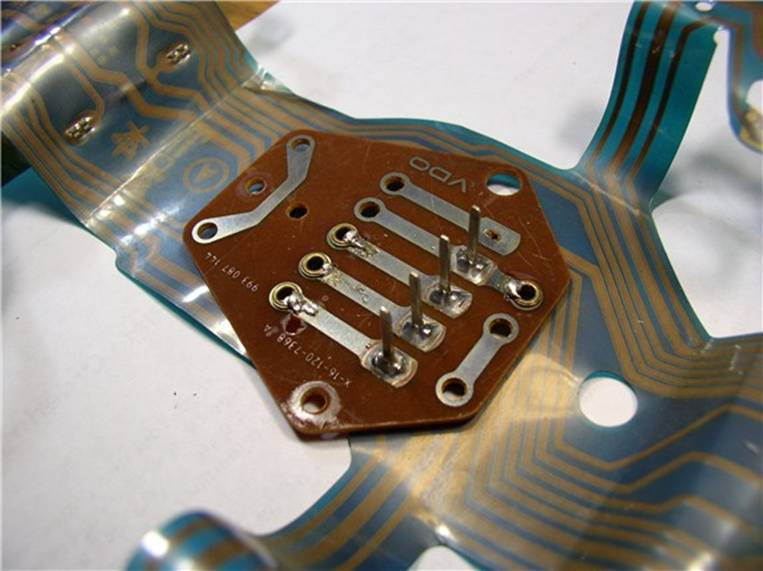

The speedometer screws are next. They take a phillips screwdriver. The speedometer also has a hard

circuit board that is riveted to the plastic circuit board through four rivets.

So in order to remove the plastic circuit board, the hard circuit board must

come off too. There are two screws that hold the hard circuit board to the

plastic instrument enclosure.

Do not try to lift the hard circuit board out just yet.

The final screw holding

the platic circuit board in place was in the corner

and was one of 6 screws used to connect the instrument enclosure backing to the front of the enclosure.

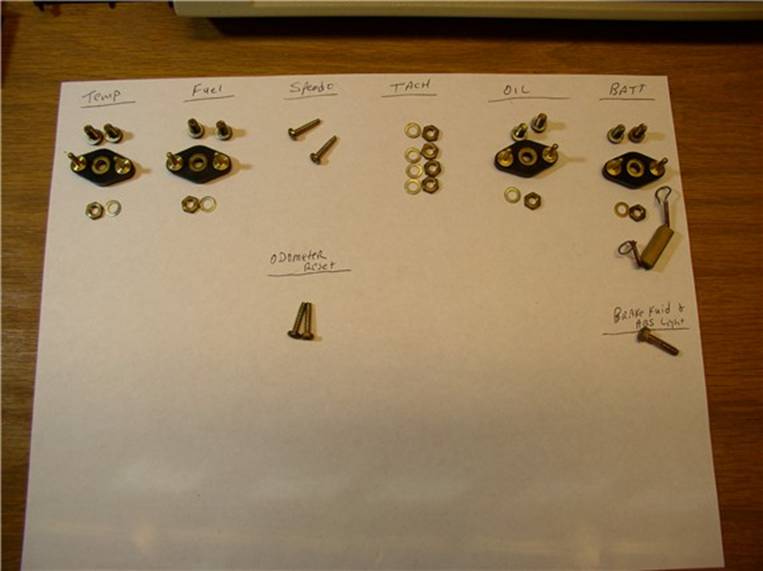

Since this was my first time, I thought it was a good idea to keep all the

hardware organized as to where it came from. It can all easily fit on an

8.5" X 11" sheet of paper.

Since you have the one resistor off, it would be a good idea to test it with an

ohm meter. This one seemed to check out OK - 68.7 Ohms on the meter while the

resistor seemed to indicate 68 Ohms rating marked on the casing.

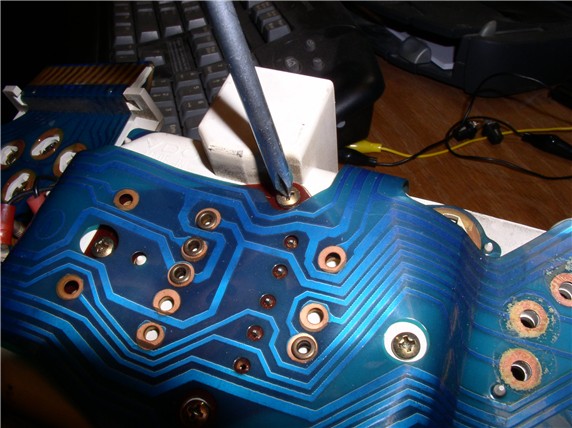

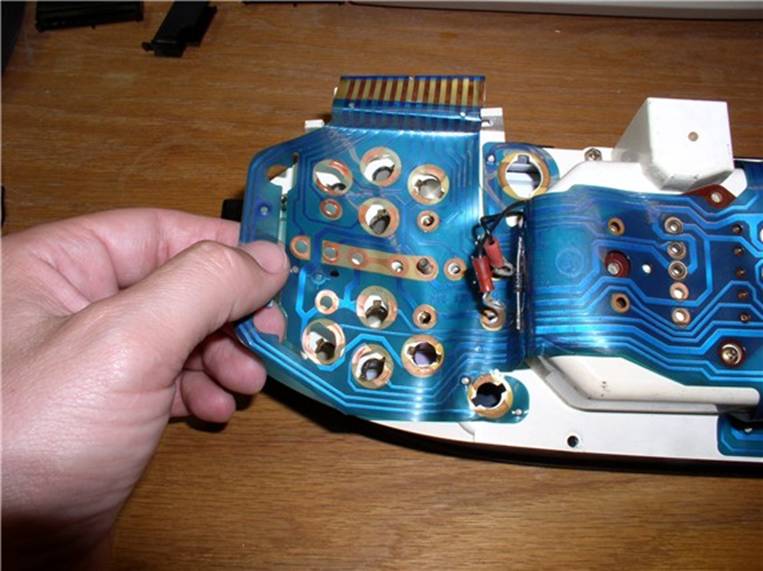

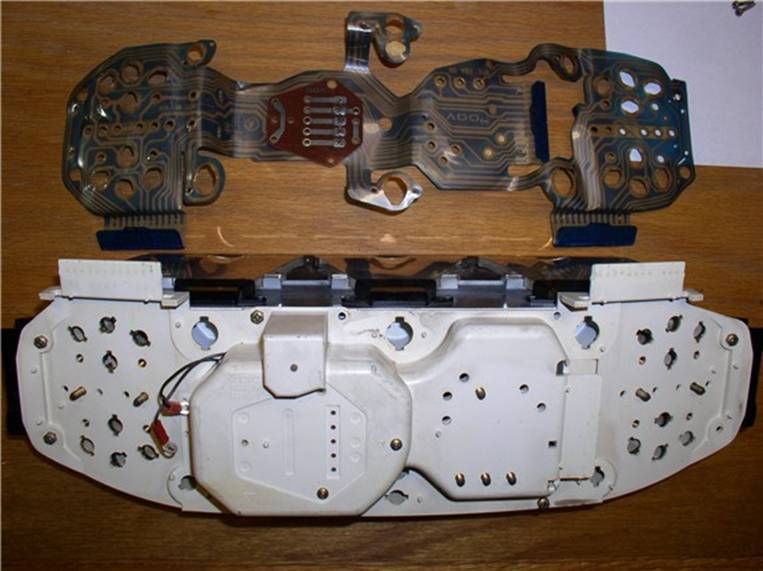

Now you can begin removing the plastic circuit board from the back of the instrument enclosure. I started with

the the left side. There are small platic pins facing upward that mate up with punched holes

in the plastic laminate. They were pretty snug so gently lift up from each of

the retaining pins by lifting up from opposite sides of the pin.

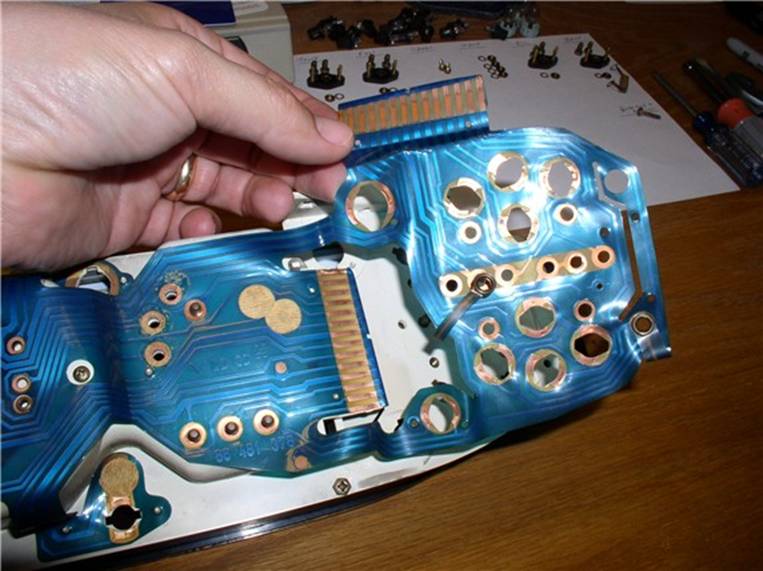

...and the same with the other side - leaving the center still attached.

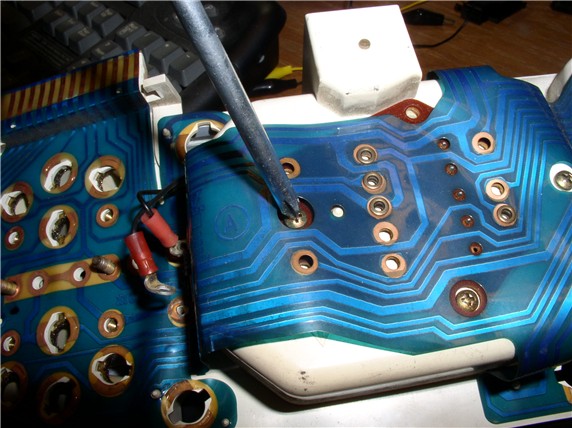

To get the hard circuit board out, you can use a small flat blad

screwdriver to gently pry the board up from underneath. There are four long

pins that connect down into the speedometer so you will want to lift straight

up as much as possible so as not to bend the pins.

Once the board is out, you can separate the plastic laminated board from the instrument cluster.

Next you can clean all exposed copper contact areas with the pink eraser. Remembering to hold the plastic firmly in place while erasing so as

not to crease the plastic board.

I noticed on the harness connections some very small writing in what looked

like german. Unforntunately,

I can't read german (except I noticed one word -

looked like blinker). I'm assuming they identify the pin connections.

Next comes the soldering. I'm a Noob at soldering -

only soldered a handful of times previously. So I was a little concerned about

melting holes in the plastic or short circuiting something will solder spill

over. When I was ordering my bulbs

from Jim at 928 Intl, he offered a non-functioning plastic circuit board to

practice with - no charge! ![]() THANKS

Jim!

THANKS

Jim! ![]()

I found the practice piece a great way to experiment with soldering techniques.

At first, I started out with a 15watt soldering iron. But it had a rounded tip

(non replaceable) and took a long time to work with. So I bought a 25watt iron

and kit with removable tips (about $17 at HD). I found the flat tips to work

much better.

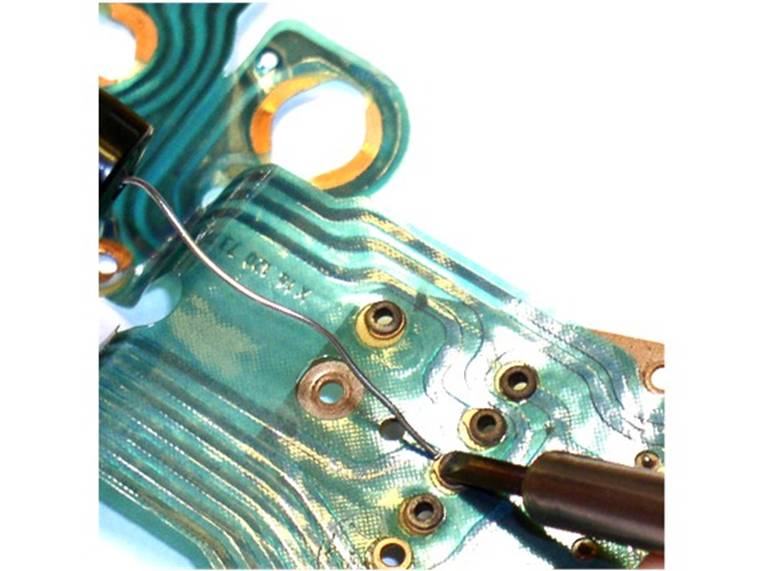

To solder the rivets, I placed the flat of the tip across the top and edge of

the rivet and placed the solder on the edge of the rivet (not on the tip of the

iron). It only takes a little bit of solder. The objective is to make contact

with the rivet and the copper material embedded in the plastic laminate at the

edge of the rivet.

Employ the same technique for soldering the rivets on the backside of the hard

circuit board.

After I practiced some soldering with what I thought was great success, I

tested the strength of the joint. Unforntunately, the

solder easily came off when I pried the solder joint with a screwdriver. I

forgot to clean the surface areas! Oh well, that's what practicing is for,

right!

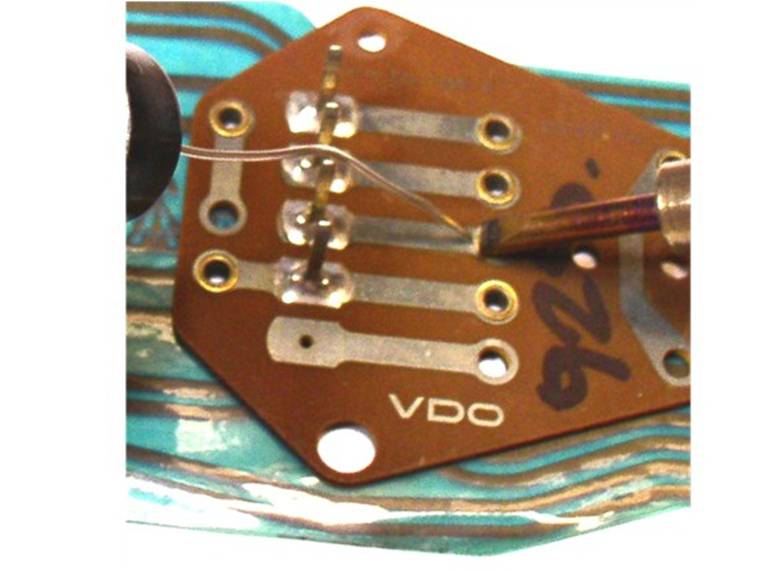

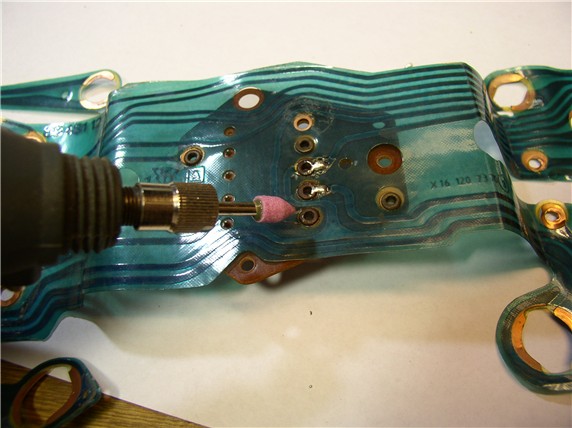

Rather than just use cleaner and a Q-Tip, I decided to really clean the rivet

surface with a grinding stone tip on a dremel. You

have to be very careful with this technique - if you slip off the rivet with

any force, you could damage the plastic laminate. I used the slowest speed,

took my time and applied very light force.

Here's the results of the cleaning with the dremel. This is probably a bit extreme for cleaning the

surface of the rivets so if you're not comfortable with it or don't have a dremel, you could use a nail file, emry

board/cloth, or fine sand paper. I reasoned that having a rougher surface would

make a stronger solder.

Before applying solder this time, I also cleaned the surrounding area with the

electronics cleaner and Q-tip since I did not believe it to be a good idea to

use an abrasive cleaning technique on the thin copper material embedded in the

plastic laminate.

After

the cleaning of rivets and surrounding area. I soldered again using the same techniques. I then

tested the strength with the screwdriver and all the joints were solid. Here's the results on the practice piece.

Then I moved to solder the REAL DEAL - I soldered the plastic side first.

Then solded the hard side (back side) next. I believe

my practice piece actually turned out better then my final version!

At this point, I was done with the speedometer repair and it was time to move

onto the fuel gauge. To get to the fuel gauge, you have to remove the front

cover. It is held in place with 6 phillips

screws (two at each end and two in the middle on my '84). One of these screws

was already taken out when the plastic circuit board was removed.

Once the screws are out, hold the instrument

cluster right side up (instruments facing upward toward the ceiling) and

holding the back of the enclosure with one hand, lift up and remove the front

cover with the other. The gauges can fall out if you hold the cluster with

gauges facing down and remove the front cover because there's nothing holding

them in at this point. I actually dropped my Fuel/Temp gauge on the floor at

one point not realizing they were just lying in place with nothing holding them

in.

Once you have the front cover off, you can inspect the innards of the cluster

for anything that might look out of place - of course, since I don't know what

I'm looking at, I couldn't tell if something was out of place or not! But I

didn't notice any broken contacts or loose wires/connections and everything

looked pretty clean.

On the gauges, you will notice resistors that will be labelled

with their rating. You can test each of these with the Ohm Meter to make sure

they check out. Mine all checked out. There was a 27 Ohm resistor at the

Alternator/Batt gauge and 68 Ohm resistors elsewhere.

Since I couldn't find anything wrong with the fuel gauge, electrically, I

decided I would simply adjust the needle about 1/8" up so that it would

lie exactly on the full line of the gauge when the tank was full. To do this,

remove the fuel/temp gauge by simply grasping at the outer edge and lifting up.

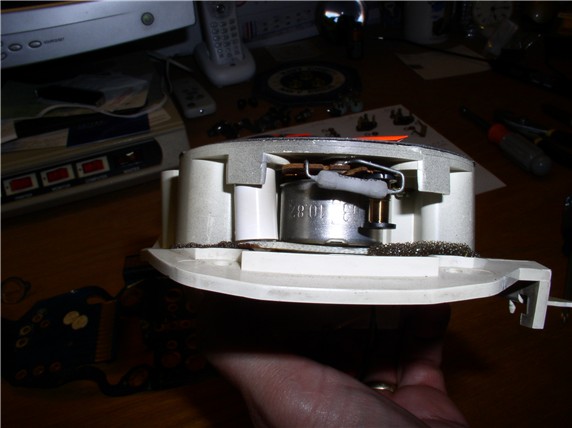

Here's a pic of the back side - nothing looked out of

place.

To adjust the needle, grasp the center cap the needle is attached to (DO NOT

GRASP THE NEEDLE ITSELF - IT CAN EASILY BEND) and rotate the needle to the

furthest top position until you feel it stop. At this point, continue to rotate

the center cap upward (counterclockwise) very carefully until you've achieved

the movement desired. In order to better gauge how far the needle actually

adjusted, mentally mark the at-rest position of the needle in relation to the

fuel gauge markings or the low fuel warning light (that's what I used) then see

where the needle rests after the adjustment. It's kind of an art but using this

technique, I figured I had adjusted it the correct amount.

At this point, you're almost ready for reassembly. First, put the fuel/temp

gauge back in place and re-attach the front cover of the instrument cluster - check for any

debris that may have fallen into the front cover before securing it. Then set

the cluster aside. Next, using the electronics cleaner and a Q-Tip, clean the

pin connectors on the gauge securing posts...

...and the pins on the speedometer hard circuit board.

Now you can begin

reassembly. Start by re-attaching the plastic circuit bard in the reverse order

of taking it off. Start with the center where the speedometer pins press into

the back of the speedometer. Then, press the plastic circuit board over the

retaining pins on the back of the cluster housing.

It was easier to use two fingers around the retaining pin and pressing down

until the plastic was flat agains the back of the

cluster housing.

There were several small round holes that had factory tape over them (to

prevent dirt/debris from entering the back of the tachometer, I suppose). The

tape had lost its stickiness and they had come off. So I used some heavy duty

fabric tape to cover the holes. I used some woven 2-sided tape and left the

seal on one side of the tape. Masking tape didn't seem strong enough to stay

and duct tape seemed a little over the top.

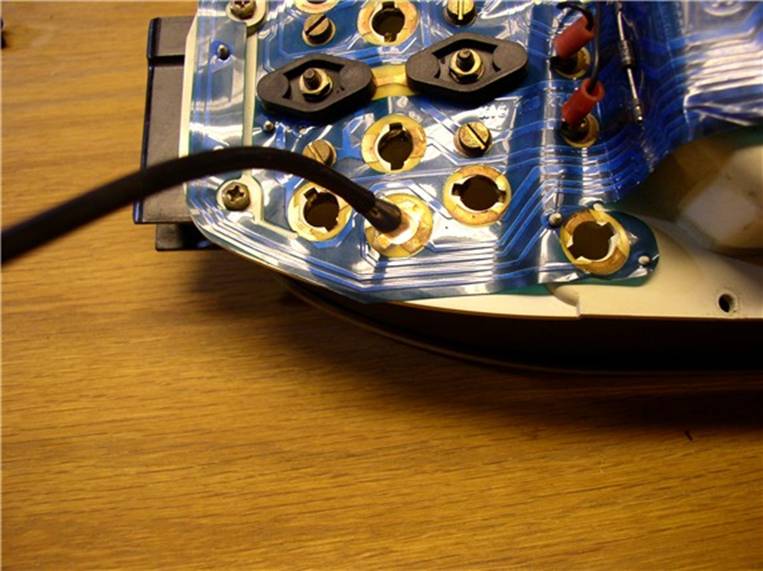

After all the nuts, screws and bulbs

are replaced and the re-assembly complete, you can take it out to the car test

it out by attaching the harnesses without the pod in place. After everything

checks out, you can re-assemble the pod.

As far as the result of my repairs, it was very successful. The fuel gauge

registered exactly on the top line when I tested it. ![]() And

the speedometer works perfectly whether it's cold or hot - no more funky behavior.

And

the speedometer works perfectly whether it's cold or hot - no more funky behavior. ![]()

![]() On

the last outing, I decided to run the fuel low enough for the warning light to

come on to see where the needle would be. This was the first time I've ever

driven it until the warning light came on because I was never sure how much

fuel I had in there before. The low fuel warning light came on when the needle

was exactly between the lower two marks on the fuel gauge which seemed about

right to me. I like the light coming on when the needle is right next to the

bottom line on the fuel gauge.

On

the last outing, I decided to run the fuel low enough for the warning light to

come on to see where the needle would be. This was the first time I've ever

driven it until the warning light came on because I was never sure how much

fuel I had in there before. The low fuel warning light came on when the needle

was exactly between the lower two marks on the fuel gauge which seemed about

right to me. I like the light coming on when the needle is right next to the

bottom line on the fuel gauge.

I just filled it up and

snapped a pic....

Please feel free to comment or provide suggestions for improvement. THANKS for

reading!