OK...here's the pics from this mornings

work...

First of all, I followed Pirtle's writeup

step by step - So he gets the credit for putting all this down in the first

place. Made things go smooth.

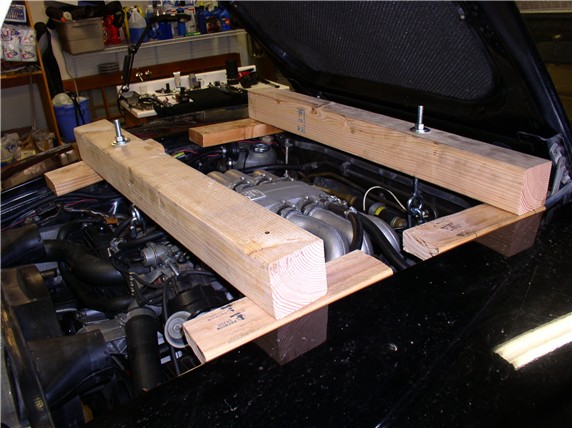

Last Weekend, I prefabricated the engine support using Andrew Olson's design.

Went to Home Depot and got a 4X4 and had them cut it to 35.25" and a 37.25" lengths. The 35.25" piece goes up front

and the 37.25" at the back of the engine. Also bought 1/2" X 10"

eye bolts (w/nuts) and large washers. All the parts were about $22. I cut some

scrap 2X4 into about 12" lenghts (4 of 'em) and counter sunk holes to fit over the fender bolt

heads/washers so the 2X4s would lay flush. I removed the hood shocks to make

room for the 4X4. Here's what they look like on the car with the hardware

attached. THANKS again, Andew! ![]()

and here's where I connected the link's to the lift

point (front)

I disconnected the battery and raised the vehicle as high as possible. About 20" from floor to lift point.

I removed the front wheels next although it would have been easier to loosen

the lugs while weight was on wheels - so I had to use an impact wrench to get

the wheels off once off the ground. Then I took off the oil filter and removed

the 10mm bolt from the wiring harness.

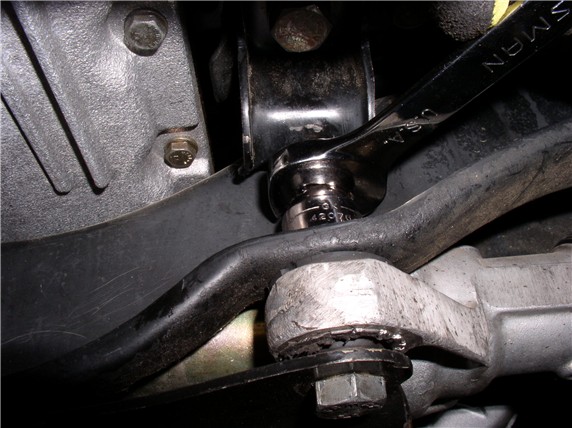

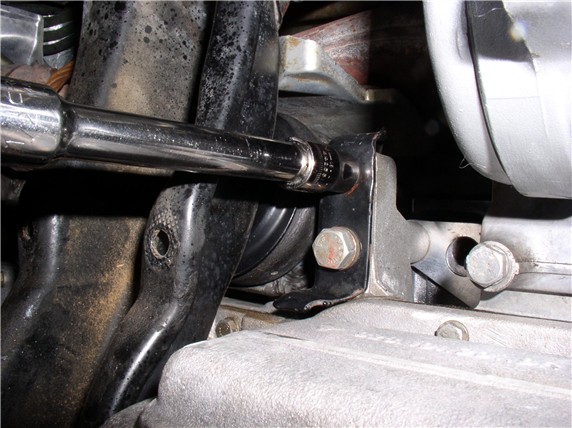

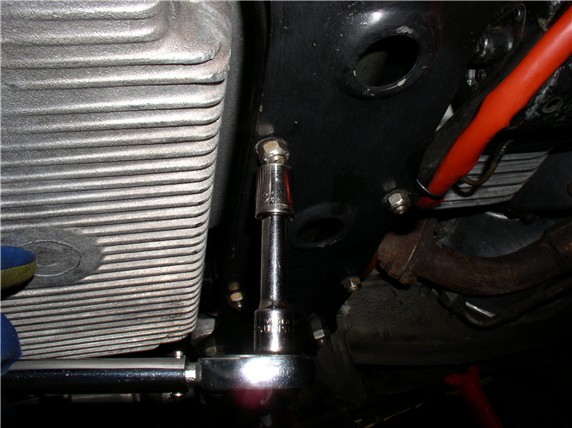

Next, I loosend the 19mm bolts connecting the sway

bar to the drop links. I used a socket wrench with a very long hanele and made loosening bolts a lot easier.

I took off the sway bar to body bolts and swung the sway bar down.

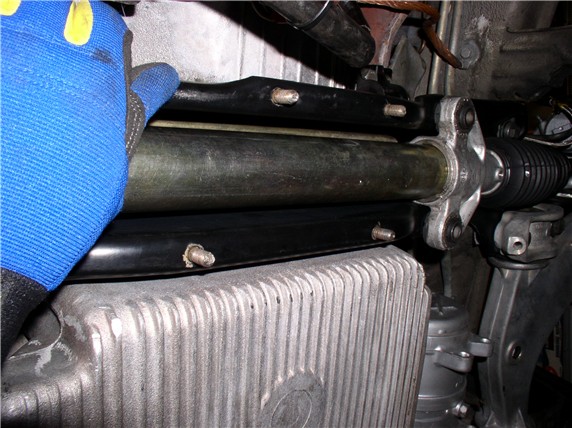

Next, I loosened the four 13mm nuts holding the steering rack plate to the

cross member

Then removed the 17mm bolt on the plate to the left of the steering rack

(driver's side)

In order to

get at the four 17mm bolts/nuts holding the steering rack, I used a short

socket that came with the ratcheting wrenches. This worked great for getting

into the tight places above the rack to counter hold the bolts

I added a step to Pirtle's process at this point.

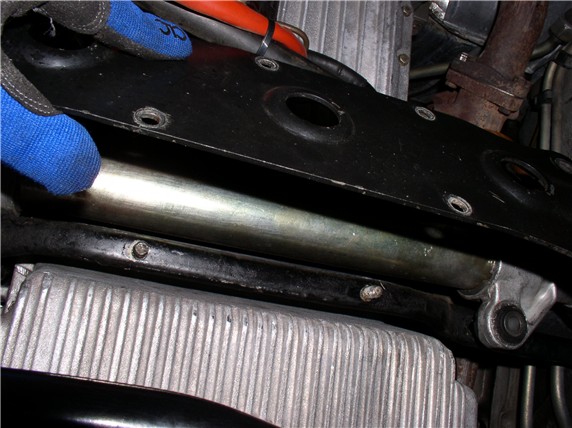

Before dropping the steering rack, I needed to take out the PS line clamp on

the driver's side fender - here's a picture of it - can be accessed either from

top or below. Just follow the PS steel lines from the rack up the side of the

engine bay and you should see it. I got to it from the top and used a 10mm

ratcheting wrench.

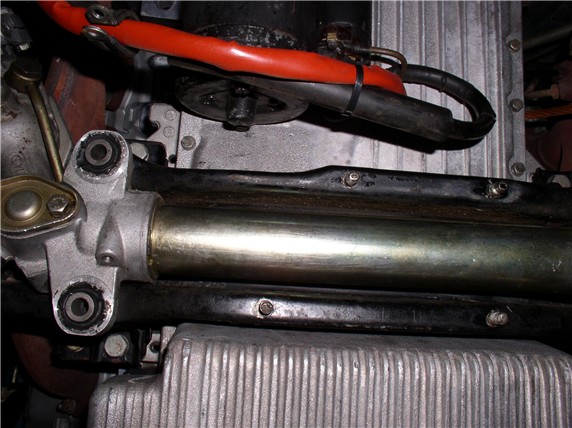

Next, I removed the four 13mm nuts holding the rack plate in place and removed

the steering rack plate.

exposing the steering rack which can now be pulled

down and maneuvered around.

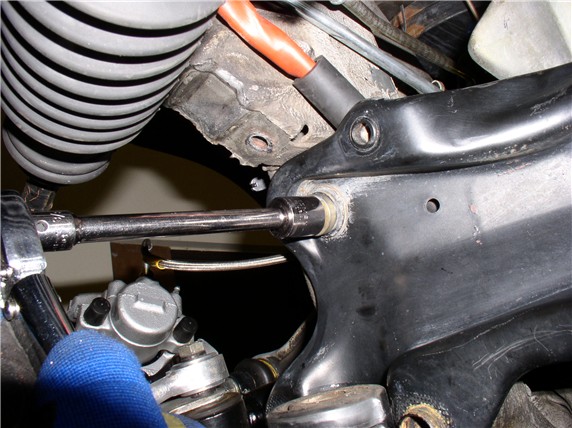

Then I loosened the 19mm nuts at the bottom of the motor mounts (under the

cross member)

And removed the 13mm and 17mm bolts that hold the mount housing to the engine

block

Next, I needed

to lift the engine - about an inch. I removed the air box (both upper and lower

halves when I put the 4X4 engine support across the engine compartment). I put

masking tape on the engine support bolt threads after snugging

the nut down by hand.

Then tightened the nut until 1" of thread was exposed below the tape - make

sure you check the clearance of the O2 sensor while lifting the engine. Mine

was OK.

Next, I removed the lower motor mount nuts under the crossmember.

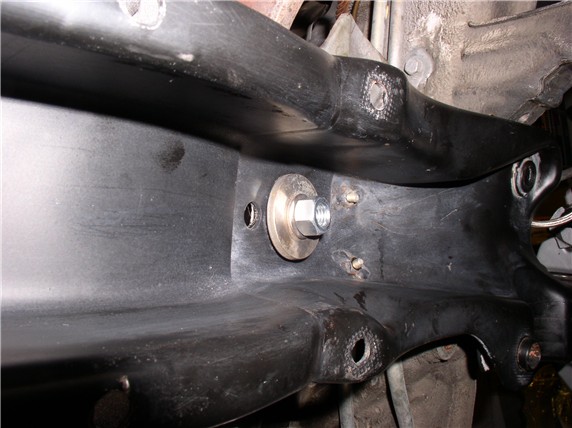

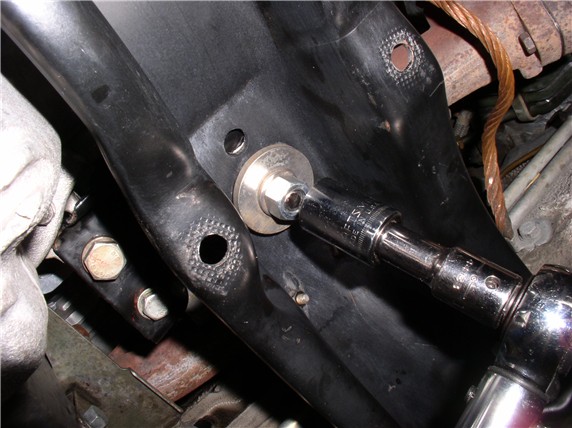

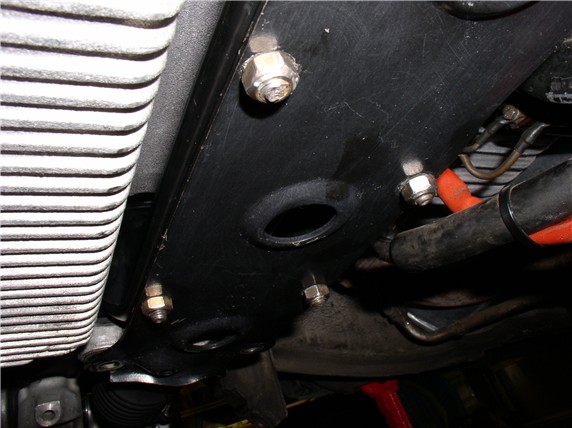

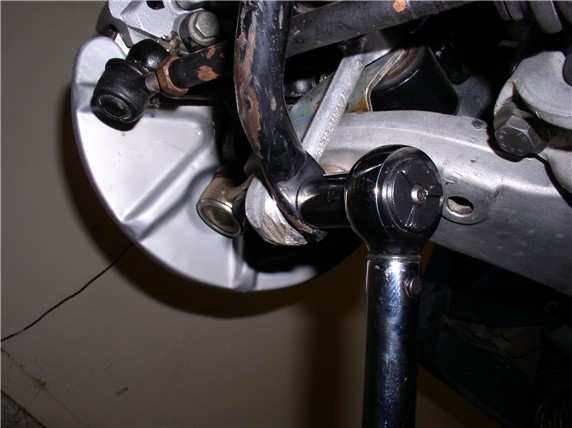

Then came the INFAMOUS crossmember upper support

bracket bolts. I was warned about these. Rather than counter hold the nut from

above in the engine compartment (as was suggested), I used a long socket

extension on the rearward nut (driver's side) and a regular socket for the

front. The passenger side did not seem to have space issues.

Here's the front bolt (driver's side):

and the rear nut (driver's side) using a long extension

The driver's side come out easy by hand. But the Passenger side required

tapping with a hammer and screwdriver. This one will be interesting to get back

in.

Next, I loosened the front 17mm bolt on the tow hook at the front of the

chassis and removed the 2nd (rear) bolt.

Then I removed the two 19mm bolts at the end of the tow hook - these are the

two bolts used to mount the front of the Lower Control Arm as well.

The tow hook should then swing down freely.

Next, I removed the two 19mm bolts at the rear of the control arm mounts

Finally, I removed the two 19mm bolts holding the cross member - one at each

end.

Then I maneuvered the crossmember down enough to

remove the motor mounts. Then some additional maneuving to get the crossmember

out completely.

After the motor mounts were out, I used the air impact wrench to get the upper

bolt off the mount.

Then I compared the old and new mounts side by side and looked for differences.

The first obvious difference is mine's flattened. Second, it looks like I'll

have to grind off the little pin in the top of the mount. And it looks like no

pin to hold the mount in place while tightening on the new mount.

I also looked at the clearance I had between the lower motor mount stud and the

steering rack banjo bolts while the rack was in the car and noticed I would have

very little room left for a longer stud on the new mount. So

I compared stud lengths on the mounts and the new one is about 1/4" longer

(actually about 3/16"). So rather than take any chances, I'll

remove about 3/16" of the threads on the lower motor mount stud.

Well, that's as far as I got this morning before I broke for lunch and posted

these pics. Now it's back to work. I'll make the mods to the new mounts first. Then I'll do some cleaning -

I actually missed a couple of bolts and there are areas on the crossmember I couldn't get to before so now's

the perfect time to do some more cleaning before reassembly. It's

Here's some pics from the progress made late yesterday on the MM mods and initial reinstall.

I used a dremel tool to cut the pin off the top of

the new MM - went quickly.

Next, I measured about 3/16" and taped the new MM lower stud so it would

be the same length as the original. The first one I used a grinding wheel to

grind it down - took about 15 minutes. The second I used the dremel - took about 5 minutes.

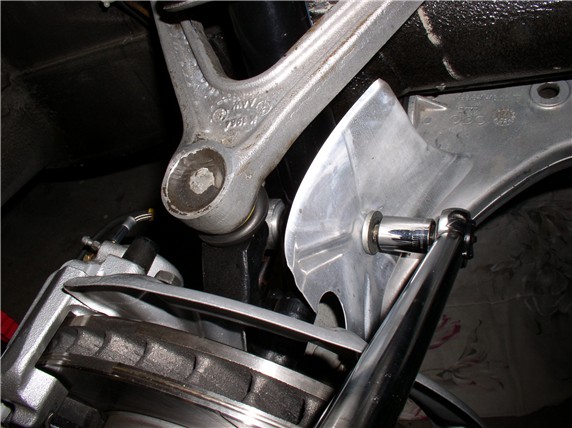

When I began the reinstallation, it started with bolting the top MM bracket to

the top MM stud and torquing it down to 62ftlb. Then getting the crossmember back into

position with the heat shields still attached. After struggling with it

for about 20 mintues with no progress, I decided to

disconnect the passenger lower control arm from the lower shock mount and

remove the sway bar as well. After that, the crossmember

was in position in about 5 minutes with no hassles.

With the cross member close to position, I tilted it back toward the rear

enough to insert/place the motor mounts (with bottom plate) bottom studs

through the hole in the crossmember. This was the

same way I took the MM out from the crossmember. I

kept the bottom plate lined up by aligning the pin hole in the bottom plate

with the alignment hole in the crossmember. Then put

the washers and 19MM nut on just enough to keep the MM from coming out.

At this point, I'm still holding up the crossmember.

Next I maneuvered the crossmember with mounts

attached up to the mounting holes in the engine block and placed the 17MM and

13MM bolts in and hand tightened. Now the crossmember

was held up and I could work on getting other bolts aligned and installed while

everything was loose.

Next, I installed the INFAMOUS crossmember support

bracket 19MM bolt. I think the key to getting these back in is to do it when

everything is nice and loose. The driver's side when in

without a hitch - just pushed it in by hand. The passenger side needed a

slight pull with the prybar to line the holes and a

few taps with the hammer and it went right in. ![]() I did

not torque these down yet.

I did

not torque these down yet.

Then I placed the 17MM crossmember to frame bolts

(one at each end) and hand tightened. Then I went back and torqued

the bolts in. Started with the MM bracket to engine block

17MM (33ftlb) and 13MM (17ftlb).

Next, I torqued the crossmember

to frame 17MM bolts (one at each end - 33ftlb).

And finally, I torqued the crossmember

support bracket 19MM bolts (62ftlb).

That's as far as I got last night. So far, time on task working on disassembly

and reinstallation only has been about 6.5 hours. Three more hours on top of

that for cleaning and setting up the grinder. Now it's about

Started at

So here's the rest of the pics

for the remaining install I did today...

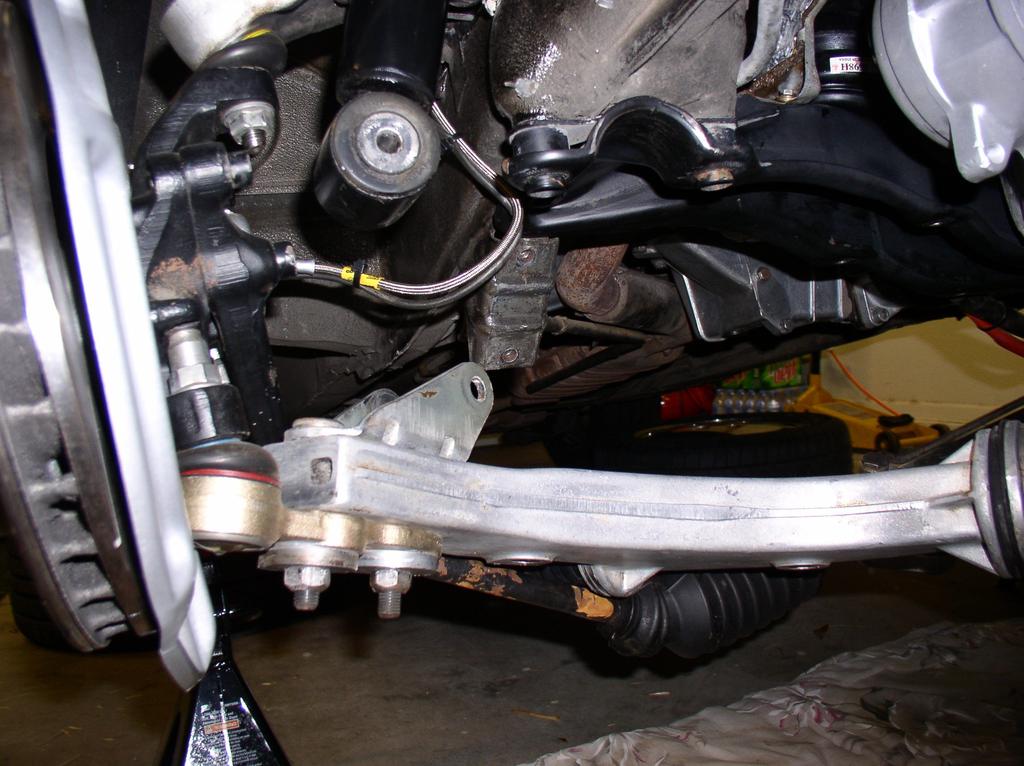

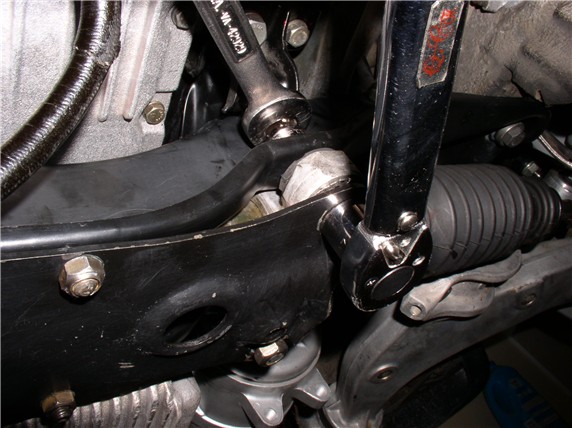

Since I removed the LCA to get the crossmember back

in, I had struggled with getting the lower shock mount to line up with the LCA

bracket - too many things under tension. So this morning I tried a different

approach and used the floor jack to hold up the hub/upper ctl

arm while I maneuvered the LCA into place. Took about 10 min.

All I did at this point was insert the bolt with the stabilizer link on the

back side to hold things in place while I re-inserted the lower ball joint stud

in the steering knuckle.

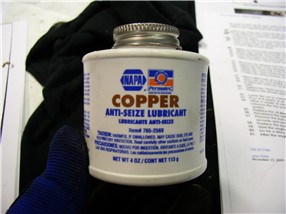

The WSM recommends applying Optimoly HT (Copper

Anti-Freeze, er Anti-SEIZE) to the Lower control arm

bolts before putting them back in (both forward and rear LCA bolts)

This is what I'm using for Optimoly HT:

And this is what I use for Optimoly TA (Aluminum

colored anti-seize):

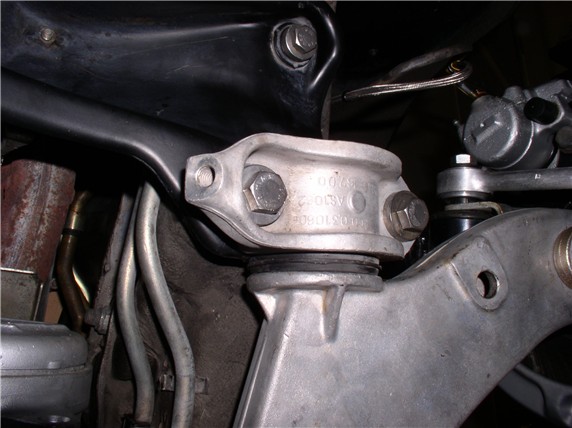

I installed the rear LCA bracket first:

I only tighten the 19MM bolts 'til there's about 1/8" gap between the

bracket and the crossmember. I read that this will

allow the car to settle easier after weight on wheels and a short drive. Then I

torque it down after the car settles:

Then I installed the front 19MM LCA bolts along with the tow eye/guard bracket.

These are torqued at this time 62ftlb.

Next, I re-installed the 17MM tow eye/guard bolt up front and torqued it down along with the front bolt - 33ftlb.

At this point, I lowered the engine. I had raised the engine 1 inch before the

install (marked by the tape)

After I lowered the engine, I measured the new engine height resulting from the

new mounts. Looks like it raised the engine about 1/2".

I removed the 4X4s and 2X4s. Someone asked what links

I used for the engine support. The eye bolt is 10" long and 1/2"

threads. These links are rated at over 2000lb for the small and over 3000lb for

the large.

After lowering

the engine, I torqued down the 19MM lower motor mount

bolt - 62ftlb.

I also made sure the alignment holes were lined up. Normally there would be a

pin here on the Porsche mounts to keep the upper and lower mount bracket

fingers aligned.

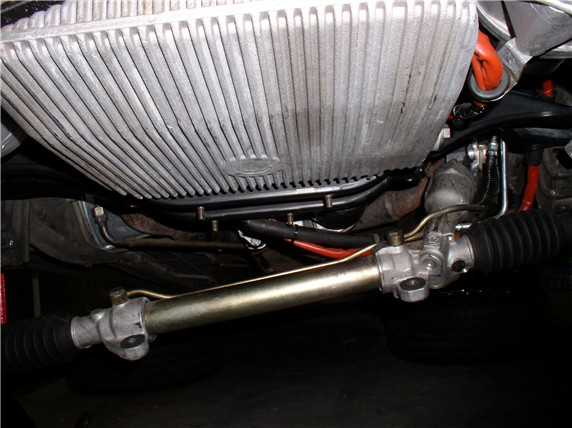

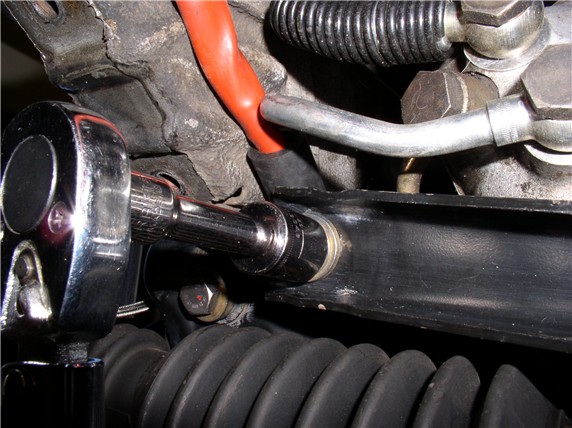

Next came the steering rack. Put the four 13MM locking

studs in the crossmember from the top.

I maneuvered the rack back into the crossmember

channel and held it with one had while getting the reiforcement

plate lined up with the 13MM studs.

Then hand-tighten the four 13MM bolts to hold the plate in place

Next, I installed the single short 17MM bolt at the end of the reinforcement

plate (hand tightened only so that the remaining four Steering rack 17MM bolts

could be lined up and assembled).

Then I installed the four 17MM steering rack bushing bolts and torqued them down - 33ftlb

Next, Torqued the single short 17MM bolt at the end

of the plate - 33ftlb

And finally, torqued the four 13MM plate nuts -

17ftlb

To finish off the steering, I then re-attached the PS line clamp to the side of

the engine compartment. Best to reach this from the top using

a 10mm ratchet wrench.

Next in order

was the starter wiring harness. Just a 10MM bolt here...

Then I installed the oil filter

The sway bar was next. I only tightened these until

they were snug. Again, I read that leaving these un-torqued

until the car settles is better. I just replaced the frame bushings last month

but still want to lubricate them. I didn't have time to find bushing lube (WSM

recommended MolyKote U - aka

dry graphite molybdenum disulphide - THANKS Wally for the fancy name! - I love

asking for this stuff at the local auto parts store - I just get blank stares ![]() ) I will

find a supplier soon and lube them up next time they are out - which won't be

long - I'm sure.

) I will

find a supplier soon and lube them up next time they are out - which won't be

long - I'm sure.

Then I torqued the 19MM stabilizer link bolts at the

stabilizer bar - 62ftlb

Next I torqued the 19MM lower shock mount to Lower

Control Arm and stabilizer link Bolt - 62ftlb

Then I replaced the air box and hooked up the air filter and air tubes.

All done underneath....

At this point, I would have put the tires back on and lowered the car, put the

engine cross brace back on, topped off the oil, and started it up. But I wanted

to check a couple other things while the car was in the air - the flex plate

tension (since I effectively raised the engine 1/2" with the new mounts)

and the crank shaft end play - more on that later.

After taking the car for a drive to let the suspension settle, I brought it

back and drove it up on ramps and did the final torque on the Lower Control Arm

rear mounts - 19MM and they are torqued to 88ftlb. Also torqued the stabilizer frame bushing

bolts - 17MM torqued to 33ftlb. Took a final

drive and DONE! and WOW...I like the new mounts!!

THANKS to all that posted on doing this job before - I learned alot before even turning a wrench on this one ![]()

![]()

![]() ....and

thanks to Pirtle for documenting the procedure!

....and

thanks to Pirtle for documenting the procedure! ![]()

![]()

![]()