While I was

replacing the engine oil filler gasket and had the car already up on jackstands this last weekend. I also repaired a bad leak

from the two hoses coming out of the PS reservoir on the '88. The fluid return

hose had a crimped connection on it so I wasn't sure if it could be repaired

without having to buy a whole new hose with the extra long cooling tube that is

routed in front of the radiator. Jim at 928 Intl said that bulk hydraulic rated

hose would work if I could manage to remove the crimp fitting. THANKS, Jim! -

That was all I needed to give it a try. So here's another procedure for curing

what seems to be a common leak problem without buying an expensive return line.

This post it Newbie-rated.![]()

In order to gain access to the two fittings at the underside of the PS pump, I

needed to remove the alternator. First, I disconnected the negative battery

terminal just to be safe (even though I had no plans to disconnect any wiring

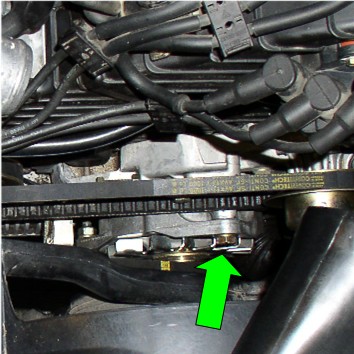

from the alternator itself). Then remove the alternator belt as well as the PS

belt. Since I was replacting the PS belt any way,

both belts came all the way off.

The alternator is held in place by a 17mm long bolt on top for pivoting and an

adjusting bolt underneath. The pivot bolt and adjusting bolt were loosened from

taking the belt off already so I simply took them both all the way out. The

alternator still hung in place after removing the bolts so rocking it back an

forth and pulling down it will work it's way loose -

do not lay directly underneath the alternator while doing this! The red

electrical connection was long enough to let the alternator hang down and rest

on a cardboard box while repairs continued. Here's a picture of the long pivot

bolt (17mm).

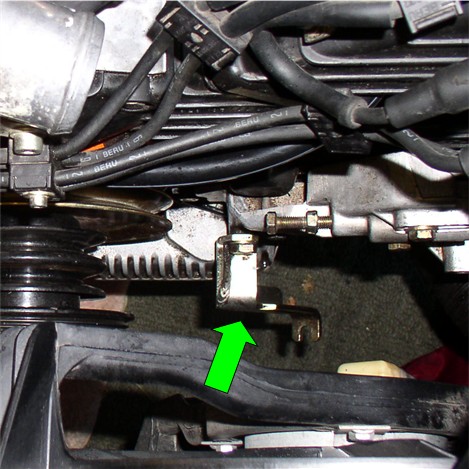

I left the adjusting bracket in place and only removed the adjusting bolt and

adjusting threads. Here's a pic of the alternator

adjusting bracket still in place after removing the alternator.

Next I set about draining the PS fluid from the reservoir. I used a clean

suction bulb (looks like a turkey baster) to draw out

as much of the fluid as I could from topside. Then I removed the suction

connection at the bottom of the PS pump (the 22mm barrell

bolt) and let the remainder drain into a bucket. After the fluid was drained

from the reservoir, I disconnected the two hose clamps/hoses at the bottom of

the reservior and disconnected the clamp that holds

the reservoir in place. Then removed the reservoir.

With the reservoir out and the suction hose disconnected from the pump, I

simply pulled out the molded suction hose from underneath the car. Here's a pic of the reservoir and old hose and new hose cleaned up.

Here's the PS return line showing the crimped fitting (next to the engine

compartment wall). I used a dremel metal cutting

wheel to carefully cut through the crimp without cutting the metal tube. With

the radiator hose already out on the other job and the fan belts removed and

the reservoir removed, there was plenty of room to work with the dremel. Even if the lower radiator hose was left in place,

I believe there is still room to work - although someone may need to verify

they have done this repair with the lower radiator hose still in place.

Here's the return fitting ready to accept the new bulk hose.

As I was looking at the original clamps used at the bottom of the reservoir, I

began thinking I wanted to use something a little beefier to clamp. I needed a

new beefy clamp to replace the cut crimp fitting anyway so here's what I

replaced the existing clamps with. You can see for the crimp fitting on the

return line, the clamping band is wider and is, of course, adjustable.

For the connections at the reservoir, I used the same beefier clamps. Here's a pic compared to the original clamps used. These clamps were

the same inside diameter as the originals.

While I was at

the imported auto parts store, I needed to pick up a new set of sealing rings

for the barrell bolts connected to the pump. The

manual gives sealing ring sizes as 14 X 18 for the pressure fitting (19mm barrell bolt) and 16 X 20 for the suction fitting (22mm barrell bolt). The shop also carried the same size inside

diameter seals but 2mm wider so I bought a bunch of the recommended size as

well as the wider size. The wider sizes are 14 X 20 for the pressure line and

16 X 22 for the suction fitting. Here's a comparison of the recommended size

compared to the wider...

I also bought hydraulic rated hose to replace the return hose. It took

7.25" and I purchased 1/2" inside diameter hose which was very close

to the original hose size. I attached this 7.25" length of hose to the

return tube first and clamped it down with the new clamp.

Then I moved to the conenctions at the PS pump.

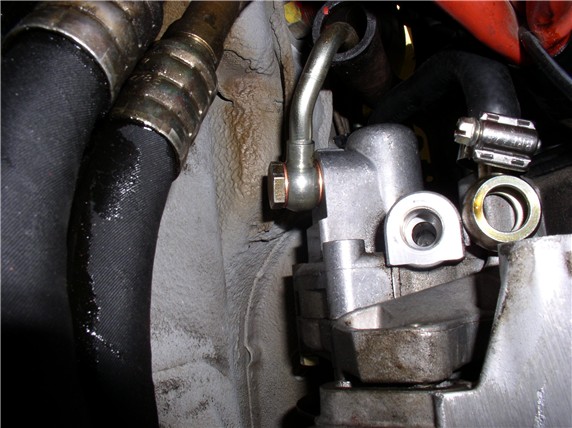

Here's a pic of the pressure fitting at the pump.

Notice the recessed groove for the sealing ring.

I test fit the new wider sealing ring and it fit very nicely in the recess. So

I went with the wider sealing rings figuring it couldn't be any worse than the

thinner originals. Here's what they look like when fitted on the pressure side.

I torqued this 19mm bolt to the same setting as the

bolts (same size) at the steering rack (22ftlbs).

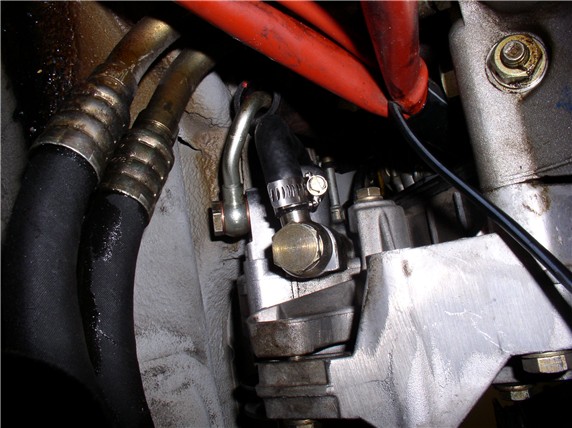

Then I connected the suction fitting at the pump (also using the wider sealing

rings). The WSM recommends torqueing the 22mm barrell bolt here to 43ftlbs. Used the

new beefier clamp here as well.

Finally, I re-installed the reservoir (return nipple - smaller one - toward the

driver and the suction nipple - larger one - toward front of the car). Then connected the return line and suction lines to the reservoir

with the beefier clamps. For all connections with the beefier clamps, I

ensured the wider clamp would fit between the barb and the hose stop on each

connection. Sorry for the blurry pic....

At this point, everything is connected and ready to fill with ATF. Probably a

good idea to fill with ATF and check for leaks before re-installing the

alternator and belts. If there are no leaks, putting it back to gether is the reverse of taking it out. Alternator first

(long pivot bolt first, then adjusting bolt) then re-install the PS belt and

tighten and reinstall the alternator belt and tighten. Reconnect the negative

terminal on the battery. Start the car and continue to look for leaks and

monitor the fluid level. I filled the reservoir full before starting the engine

but after running, the fluid level went down to normal level (after the new

hoses and the pump were filled).

Hope this is helpful to some - feel free to comment or suggest improvements to

this procedure. THANKS for reading!