Pod Removal and Instrument Cluster

Repair w/pics (Part I)

†On the '84, I've been having problems with my

fuel gauge not registering full (only 3/4 full) on fill-ups and my speedometer

stopped working when it was cold (after the pod heated up from sitting in the

sun, it worked but not accurately). So, after much troubleshooting to narrow

the problems down, it looked like the problem was in the instrument cluster - everything else checked out.

I had never removed the pod before or worked on the instrument cluster but I found several excellent writeups on the procedure which made it much easier. This forum as well as several other 928 owner websites have

been priceless resources to me! THANKS!! ![]()

![]()

I snapped a few pics along the way for those like

myself that have not tried this before - my fellow noobies!

There's quite a few pics so

I broke it into 2 parts. This first part is for pod removal and installation on

the 1984. In part II, I have pics of cleaning and

repair of the instrument cluster.

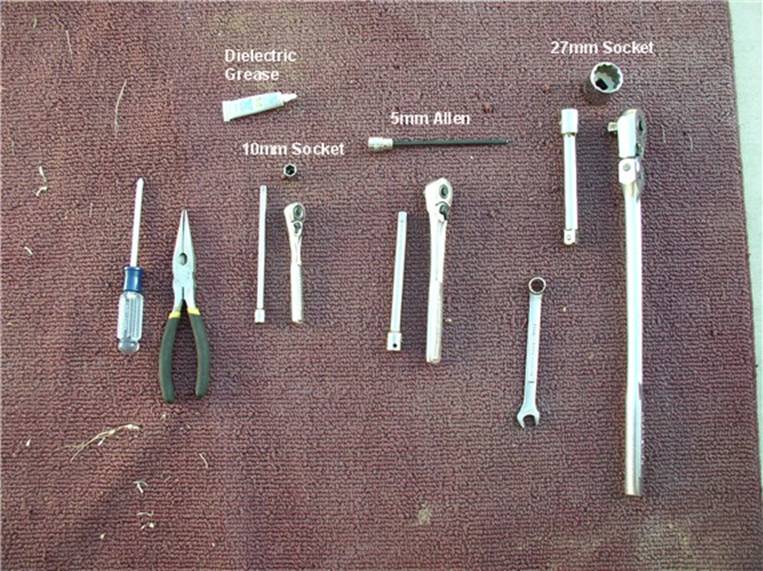

First, gather the tools needed. Here's a list and a pic

of the tools I used:

1. 27mm socket

2. 10mm socket

3. 5mm allen wrench/socket

4. 13mm combination wrench

5. Needle Nose pliers

6. Phillips screwdriver

7. 6" extensions for socket wrenches

8. Dielectric Grease

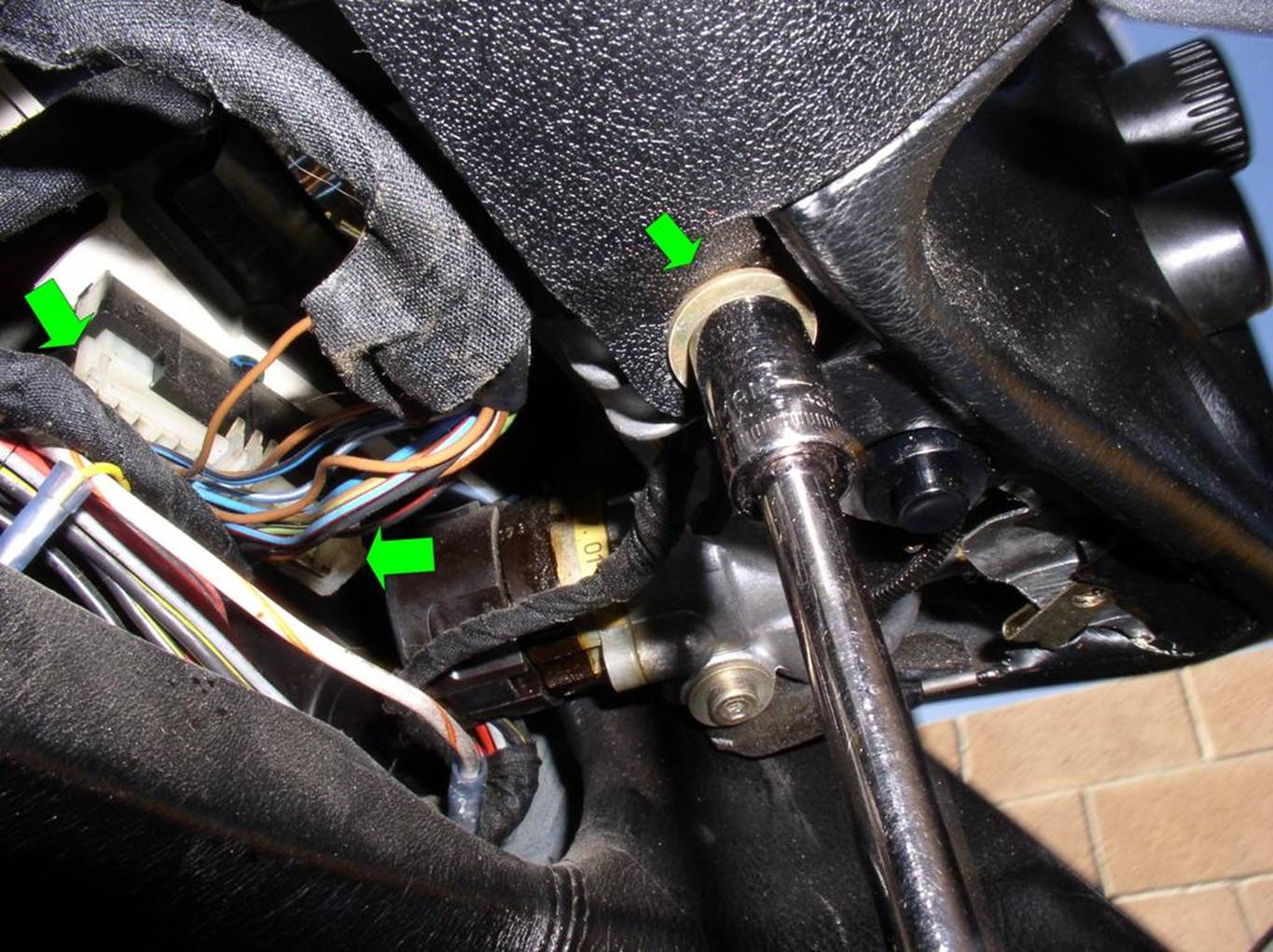

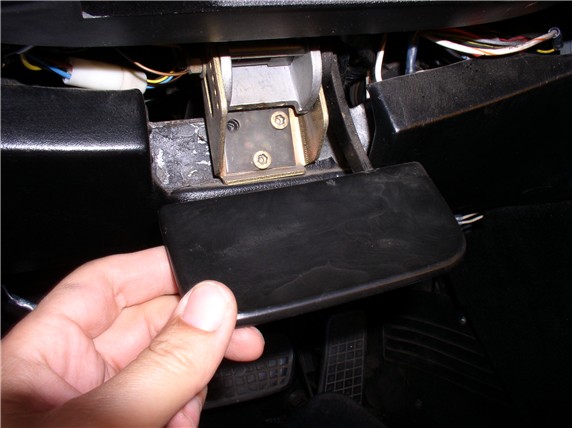

Next step is

to take off the front cover. It's held on by two 10mm bolts (left and right)

and a phillips screw. Take

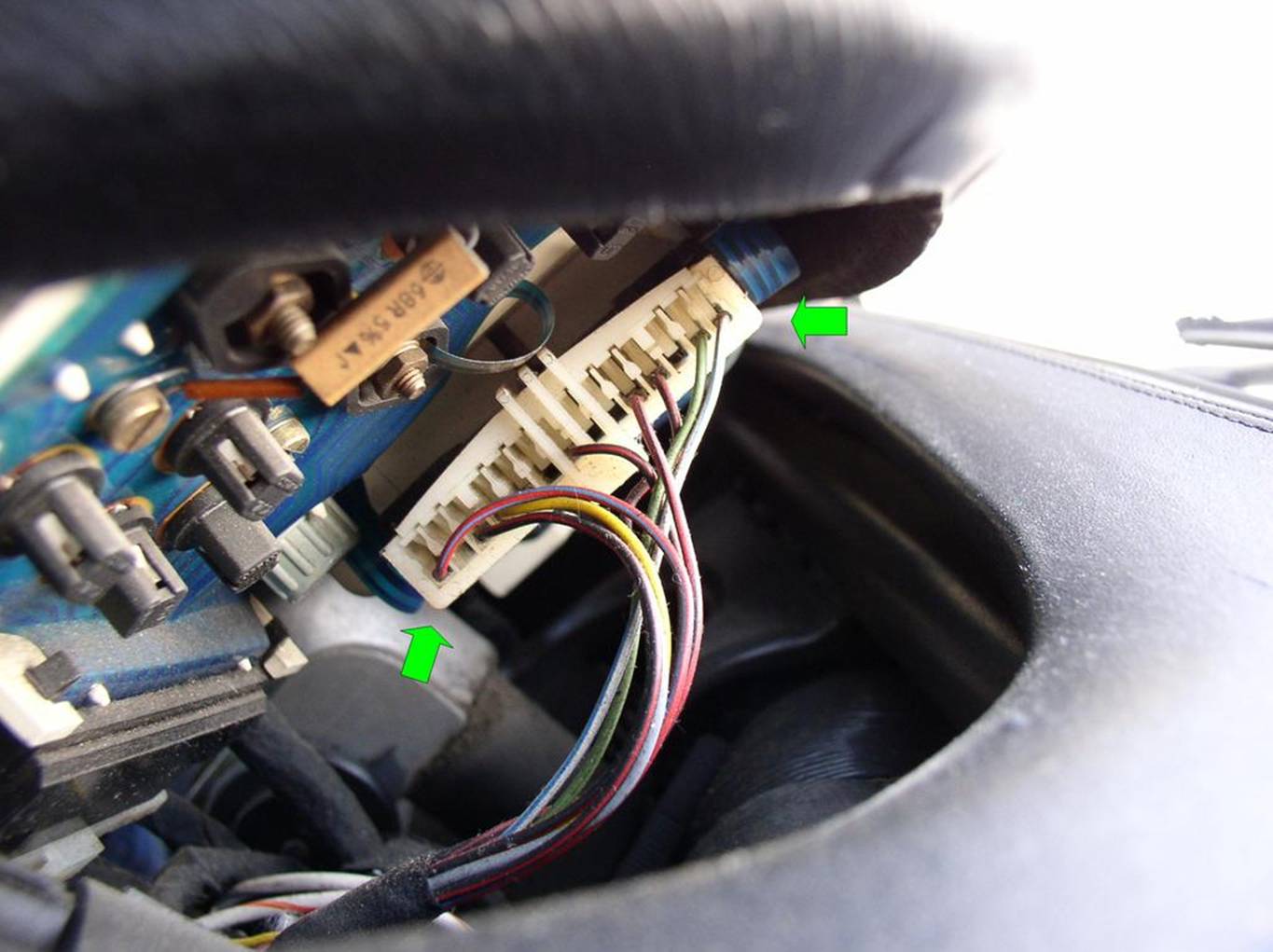

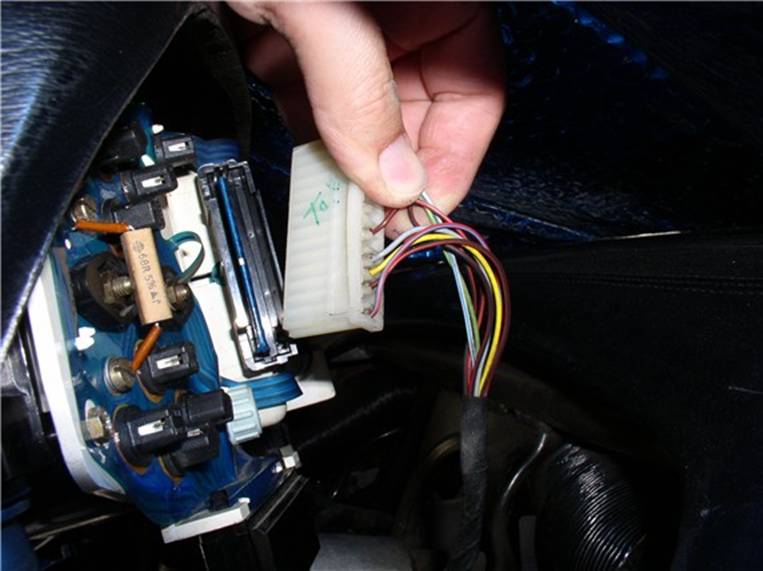

off both of the 10mm bolts. You may also notice that the lower instrument cluster wire harness plugs are now

visible from underneath (see arrows). There are three instrument cluster wire harness plugs on the cluster. Two of these are underneath -

one on the left and one on the right (you can see the right one in this pic). The third harness plug is best accessible from behind

the pod after the pod securing bolts are removed. For now, you can remove these

bottom two plugs by gripping them by the white platic

ends and working it slightly left-right while pulling down. If you don't find

you have the room here, you can disconnect them later when the pod securing

bolts are removed and you can lift the pod slightly to get at the plugs more

easily - that's what I did.

Then take out the phillips

screw...

With slight maneuvering, the front cover will now come off.

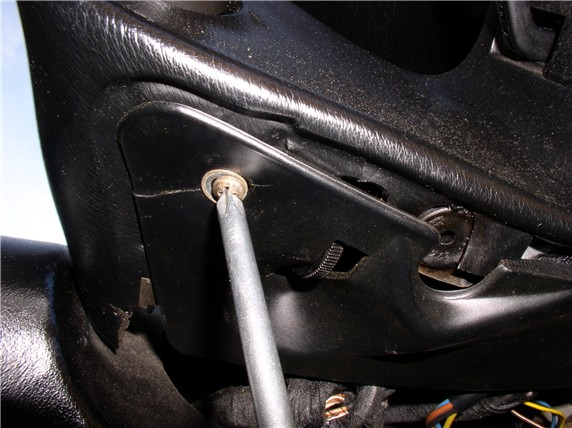

The pod is held in place by two 5mm allen

head bolts (left and right). I took the right side out first. It's located

right next to the ignition switch. I had to lie down on my back to see it (as

well as the left allen bolt

on the other side).

Then take out the left side allen

bolt. It's located to the far left of the pod right about where the left edge

of the instrument cluster is.

The two pod securing bolts are pictured here. The longer bolt on the left

secures the left side of the pod - the shorter secures the right of the pod.

Next, remove the ignition switch rubber gasket. It stretches and will easily

pull off. If you can't get at it with your fingers, you can pry one side off

easily with a screwdriver.

I read in some writeups that you can remove the pod

while the wiper/signal/cruise cluster

is still in place. However, I liked the idea of removing it for ease of getting

the pod out and back in again. To remove it, I pulled the pod forward enough to

clear the ignition switch then lifted the pod up enough that the

wiper/signal/cruise cluster

would clear the pod if I were to pull it straight out.

Once the pod is lifted up enough, pull the wiper/signal/cruise cluster toward you with a

twisting-walking motion and it will slowly move outward toward you. Mine was a

snug fit but eventually pulled away from the steering column and pod. When it

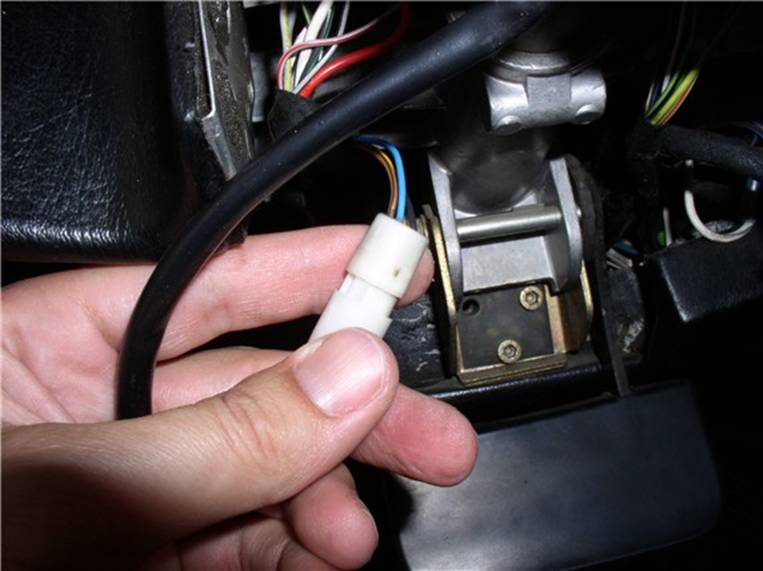

clears the pod, you can lower the pod. At the back of the wiper/signal/cruise cluster, are two wiring connectors

(one left and one right). I found it easier to disconnect

these two connections first before completely removing the cluster from the column (the wires

aren't quite long enough to clear the end of the column without quite a bit of

strain).

With the connections off, the cluster

comes off the steering column.

Lastly, disconnect the barrel connection for the wiper/signal/cruise cluster and set the cluster aside.

Next, I disconnect the negative terminal of the battery using the 13mm comb. wrench.

Then remove the horn pad. Sitting in the driver's seat, grab both ends of the

pad and pull firmly toward you - but make it a shallow pull because there's a

wire connected to the back of the pad you don't want to damage. It has about

4" of play in it.

After the horn pad comes out, tilt if forward and you can see the horn wire

connected to the back. Disconnect it.

Then, using the 27mm socket and 6" extension, loosen the steering wheel

nut. I used a long handle socket wrench to get more leverage. I held the

steering wheel with one hand and applied the wrench with the other. It came off

without any problems but if the nut is really tight, you may have to tie the

wheel down or block it with something to hold it in place. I was not

comfortable applying force against the steering wheel locks. Loosen the nut but

do not take it all the way off. With the nut loosened, pull the steering wheel

to get it loose but still on it's splines. Some steering wheels will not come

off easily and this procedure will allow you to loosen the wheel from the

steering column splines without the wheel coming up to meet you in the face!

With the wheel loose, remove the Nut - but DO NOT TAKE THE STEERING WHEEL OFF

YET.

Before taking the wheel off, you need to mark its orientation so you can get it

back on in the same position. You can mark it with a piece of tape. I simply

centered the wheel perfectly then pulled the wheel. This worked fine for me

since I wasn't planning to move the car while I was working on it.

To get at and remove the plastic covers unterneath,

move the tilt wheel paddle down.

First, remove the two phillips

screws that hold the bottom plastic cover in place. There's one on the left....(as you can see, mine is cracked from someone overtightening the screw - which seems to be very easy to

do if not careful)

...and one on the right...

The lower plastic cover doesn't just drop down. It has 4 thin plastic fingers

that insert under the front plastic cover. You will need to slide the lower

cover back to allow the fingers to clear the front cover. Do this carefully,

the fingers can easily break.

Once the fingers are clear, the cover can be pulled down and out. Here's a pic with the cover out. As you can see, one of my plastic

fingers was already broken off.

The next item

is to take the lights/odometer reset/defroster/hazard knobs off. These simply

pull straight out and off. I removed all five at this time. However, make a

note of what order they are in. Lights top left, fog lights middle left,

odometer bottom left, defroster top right, hazard middle right. My visual

memory must be failing me ![]() because

when I first pulled them off, I only remembered for sure that the light switch

was top left - had to refer to a picture to remember the rest!

because

when I first pulled them off, I only remembered for sure that the light switch

was top left - had to refer to a picture to remember the rest!

Once the knobs are off, you will see the switches are held in place by two

plastic tabs (one on top of the switch and one on the bottom). Use the

needle-nose pliers to compress the tabs in and at the same time pull the switch

out - using a twisting motion left to right helps.

Pull the switch out all the way until you see the wires at the back of the

switch connector.

The switch connections are keyed. However, to ease the re-installation, mark

the switch as well as the harness connection so they can be easily

re-associated when putting it back together. For example, the convention I used

was 1L for "top left switch", 1R for "top right switch), 2R for

"2nd right switch from the top", etc.

Once all the switches were out, I re-attached the knobs with the switches just

to keep them together.

Next the harness connectors for all the removed switches can be pushed back

into the pod.

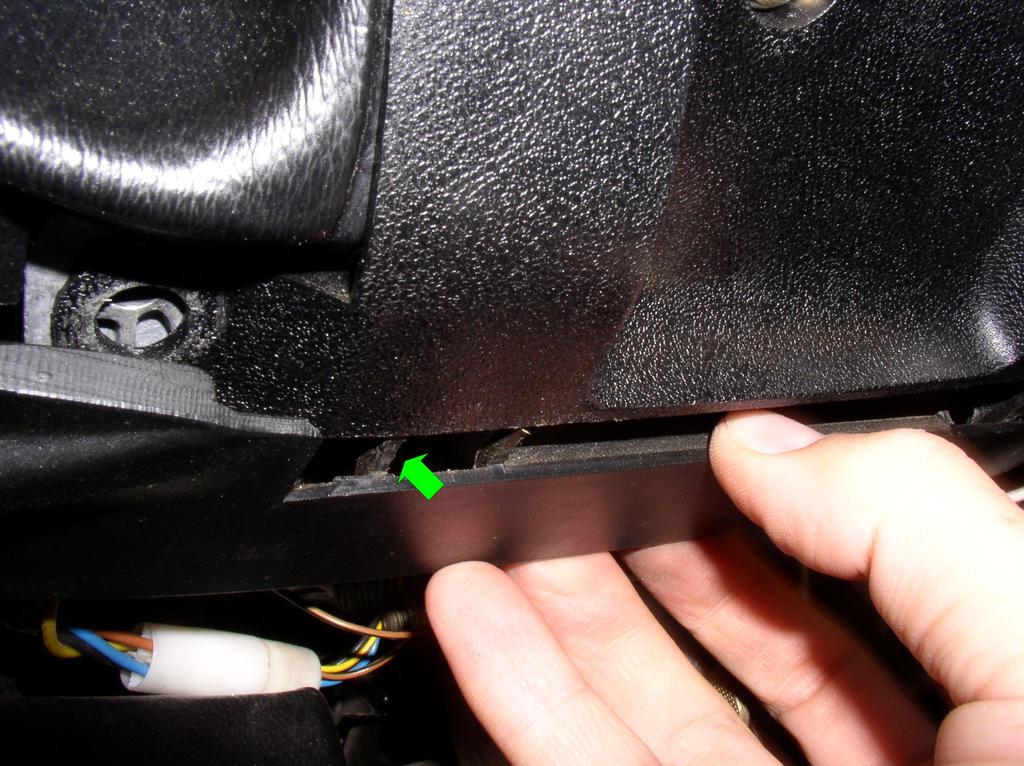

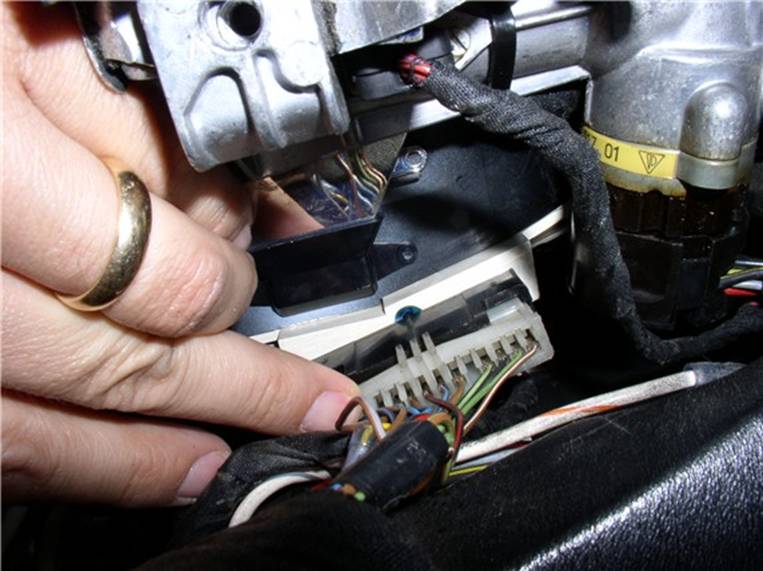

The rear instrument cluster

wiring harness needs to be disconnected next. The pod can now be moved up and

forward to gain access to the rear. You will find the rear harness to the right

side of the pod. Pull the right side of the pod toward you and find the wiring

harness. You can grip it with you finger and thumb at the green arrows shown

and pull on it while walking it up and down and it should come out. If you have

not removed the bottom two (left and right) wiring harnesses from the

instrument cluster yet,

now would be the time to do so. You can gain access to them by lifting the pod

up and pulling down on the white plastic connector as before.

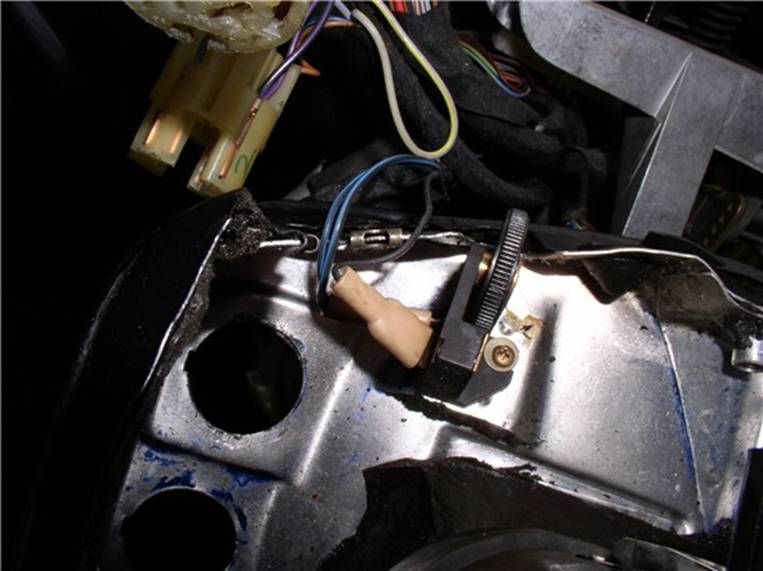

There are just a few more wires to disconnect from the pod. With the inst. cluster wiring harnesses disconnected,

you should be able to lift the pod and pull it toward you and lay it face down

to expose the back side of the pod and instrument cluster. To the left you will notice

two wires connected to a thumb wheel. This is the instrumentation light dimmer

switch. Disconnect these wires remembering which terminal the double wire is

connected to.

On the right side there are two more switches. The small black push button

switch operates the intensive windshield washer pump. It is barely visible

behind the yellow wires in the pic - it has purple

and black wires going to it. Disconnect these. There are also two wires (shown

yellow in the pic) that attach to another thumb

wheel. I didn't know what this wheel did until just this morning when I read a

post about it. PERFECT TIMING!! This forum is GREAT! ![]() The

right thumb wheel controls the duration of the delay interval for the

windshield wipers. Disconnect these wires as well noting which terminal the

double wire connects to. In reality, I suppose it's not terribly important to

keep the terminals/wires matched on the thumb wheels. If they are reversed, it

would only mean the polarity of the wheel would be reversed and dimming action,

for example, would occur in the opposite wheel direction than the factory

install (i.e., dimming by moving the wheel toward you vs

moving the wheel away from you).

The

right thumb wheel controls the duration of the delay interval for the

windshield wipers. Disconnect these wires as well noting which terminal the

double wire connects to. In reality, I suppose it's not terribly important to

keep the terminals/wires matched on the thumb wheels. If they are reversed, it

would only mean the polarity of the wheel would be reversed and dimming action,

for example, would occur in the opposite wheel direction than the factory

install (i.e., dimming by moving the wheel toward you vs

moving the wheel away from you).

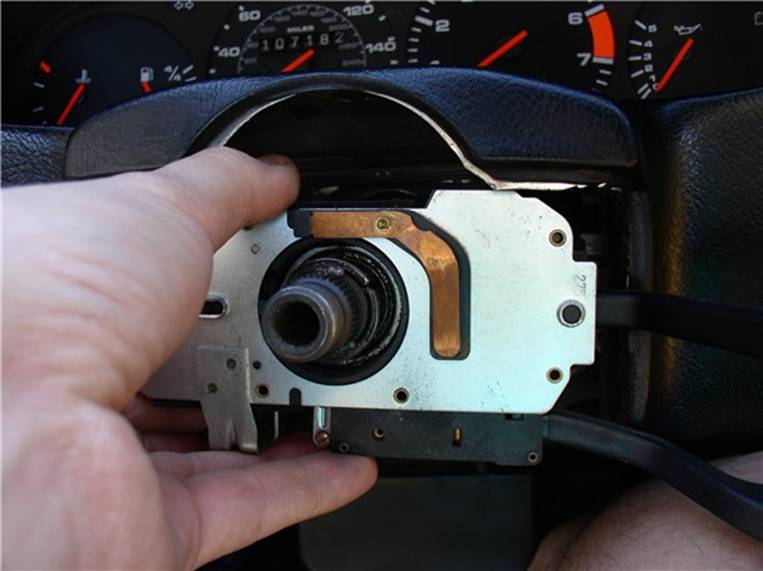

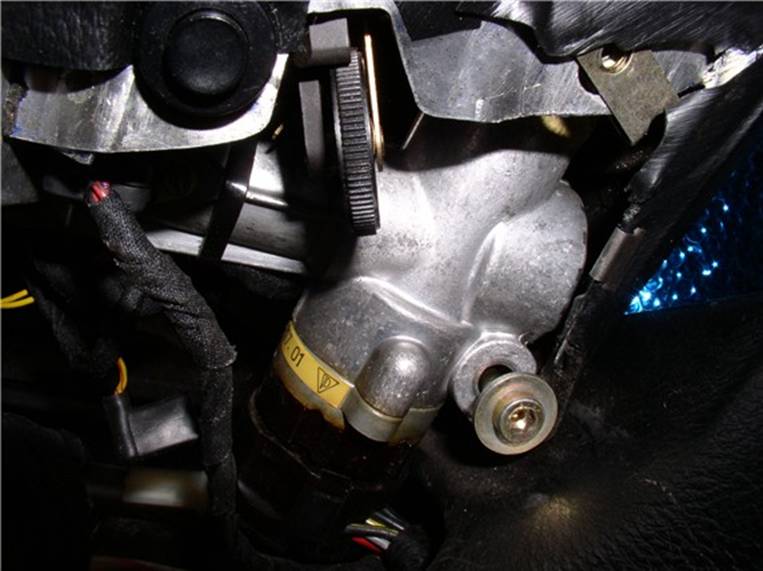

The pod and instrument cluster

can now be removed from the car. This next step is optional and involves

removing the post/bolt that helps secure the right side of the pod to the

ignition branch of the steering column. You should be able to simply pull the

instrument cluste raway

from this post to separate the cluster

from the pod. However, I didnít realize this before I decided to disassemble everything ![]() . If

you do decide to remove the final cluster

retaining bolt, make a note of it's orientation

because it will need to be realigned with the hole at the ignition switch that

takes the 5mm right side securing allen head bolt.

This difficult to do while the instrument cluster

is in the pod during re-install. This last bolt also takes a 5mm allen wrench/socket. On the

re-install, I documented a procedure to line up the holes again in case you

don't mark the orientation.

. If

you do decide to remove the final cluster

retaining bolt, make a note of it's orientation

because it will need to be realigned with the hole at the ignition switch that

takes the 5mm right side securing allen head bolt.

This difficult to do while the instrument cluster

is in the pod during re-install. This last bolt also takes a 5mm allen wrench/socket. On the

re-install, I documented a procedure to line up the holes again in case you

don't mark the orientation.

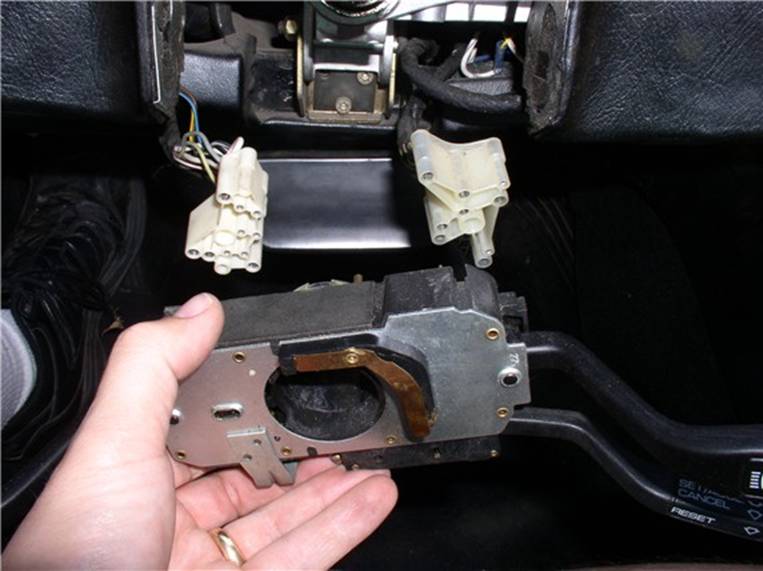

At this point, you can take out the bushings that hold the instrumentation cluster. Just two bushings on the left

side....

...and the bushings with the securing post on the right (if you removed it).

At this point the cluster is

removed.

Now you can work on the cluster

or the pod. Now's also a good time to look in the dash where

the pod was for anything that might be amiss. For example, I noticed

that the HVAC side vent hose had separated from the central unit so I

re-secured the hose. At this point, I began working on cleaning and repairing

the instrument cluster.

I'll post the pics on that effort under a new post.

After you've completed the pod/instrument cluster

work and you're ready to put it back in, I have pics

of the re-install next.

The re-install

process is pretty much the reverse of the removal but I had pixels to spare on

the camera so snapped a few pics on the way.

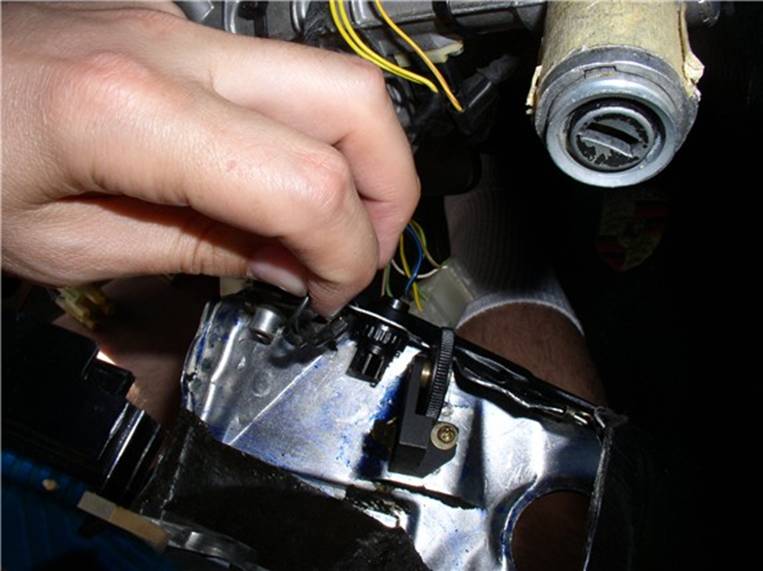

If you didn't remove the right instrument-to-pod securing post with bushings,

you can skip this first step and pics. For those that

removed it like I did, here's what I did to get it installed and aligned with

the ignition switch. First, I placed the post and bushings as they were to be

oriented when installed. As you can see the allen bolt that secures this post to the pod is

blocked from below by the ignition switch (right next to my pinkie in the pic).

Next bolt the post and bushings into the empty pod and snug the allen bolt down with the 5mm allen wrench (but leave it loose enough that it can swivel

with moderate force).

Then place the empty pod into position. Reach inside the pod and rotate the

bottom of the post so that it lines up with the hole in the ignition switch.

This pic was taken from inside the empty pod.

Verify the alignment is correct by screwing in the 5mm allen head securing bolt from beneath the ignition

switch. Reach inside the pod to make any fine adjustments to get the alignment

right. Once the bottom bolt goes in freely, remove it.

Carefully remove the pod so as not to distrub the

orientation of the bushing post and turn the pod upside down. Holding the end

of the bushing post firmly to prevent movement, finish tightening down the 5mm

bushing post.

Now, ready to insert the instrument cluster.

First, install the two bushing on the left side of the instrument cluster.

Then slide the right side of the instrument cluster

into the bushing post on the right side of the pod.

Next, attach the black harness locks onto the three harness receptacles on the

back of the instrument cluster.

Each of these locks has a small pin that protrudes from one of the horizontal

edges. This pin is oriented toward the bottom of the instrument cluster connector (i.e., side opposite

the side facing up with the metal contacts exposed). The black plastic locks

are secured by two locking tabs (one on each end). Press the locks in place

until the tabs interlock.

Then, take the pod and instrument cluster into the car and place it face down

on your lap up next to the steering column. Re-connect the wires to the

instrumentation lighting dimmer switch on the left of the pod....

...and re-connect the intense washer fluid pump and wiper delay thumb wheel

wires on the right side of the pod.

Next, rotate the pod upright and place into position above the steering column

and pull the lights/odometer reset/defroster/hazard harness connectors through

their respective holes in the pod. If you numbered them previously, they will

be easily identifiable. The way I got them started was to grab the wires

associated with the switch connector from below and push/maneuver the connector

up to the hole. Then I used my fingers on my other hand to guide the connector

through the hole just enough so I could grasp the connector and pull it through

the hole.

Pull all the connectors through their holes enough so they will stay in place

while you continue working.

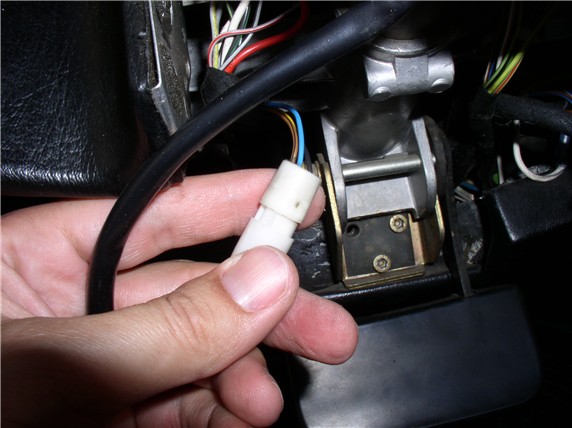

Next, connect the right

rear instrumentation cluster harness. Pull the right side of the pod toward you

to gain access to the back right side of the pod and push the connector firmly

into the receiver on the back of the cluster.

Then, install the wiper/signal/cruise cluster onto

the steering column. Position it in place....

...and attach the two wiring harness connectors at the rear before pushing and

seating the signal cluster - otherwise, you will not have room to connect the

harnesses once the cluster is fully seated on the column. Ensure the wiring

harnesses are fully seated against the cluster.

Re-connect the barrel connector.

Lift the pod enough for the wiper/signal/cruise cluster

to clear the pod and push in on the signal cluster

with a twisting-walking motion to work it down until it is fully seated and

oriented so that it is level.

Next, position the pod so that the ignition switch is lined up with the hole in

the pod and push the pod onto the ignition switch. Then line up and insert the

left (long) 5mm allen head pod-securing bolt and

screw down but leave it loose until the right side is attached.

Install and tighten down the right side 5mm allen head pod securing bolt that goes through the

ignition switch. Before tightening these bolts, I made sure the pod was not in

contact or rubbing against the dash or other obstacles so as to reduce

vibration noises. Go back and tighten the right side 5mm allen head bolt after securing the right side.

Next, connect the left instrumentation cluster

wiring harness from below. You can also re-connect these harnesses from above

before you bolt down the pod.

And connect the right instrument cluster

harness from below.

Now, connect the lights/odometer reset/defroster/hazard switches with their

respective harness connectors....

....and re-insert them into the pod. Note the orientation. There is a square

notch on the front of the switch that is to be oriented to the top. The knobs

are keyed to this notch and will ensure the knob is correctly oriented when

re-installed. Press the switch in until you hear/feel the plastic tabs click

into place.

Next, attach the knobs with their respective switches. Simply line the notches

up and press in firmly until you hear the tabs click/lock into place.

At this point,

I started the car to make sure everything was still functioning. When I was

working on the instrument cluster

- before installing it in the pod - I had also tested the repairs to ensure

everything was working. Re-connect the battery and start the car and check

instrumentation functions and switch functions before the final assembly. I was

very pleased with the fuel guage functioning

correctly now - a full tank shows full on the gauge now.![]()

![]() My

wife thinks I'm nuts for going through the trouble of fixing this little

problem. What can I say??....it's the little 928 repair victories in life that

makes it all worthwhile!

My

wife thinks I'm nuts for going through the trouble of fixing this little

problem. What can I say??....it's the little 928 repair victories in life that

makes it all worthwhile!

Next, install the front plastic cover. Maneuver the cover into place....

...and tighten the two 10mm bolts. I left the bolts a little loose so I could

adjust the cover to line up the hole for the phillips screw.

Install the phillips screw

but don't tighten all the way. Then, line up the front cover so that it fits

snugly up against the mating edge of the pod and tighten the phillips and 10mm bolts while

holding it in place with one hand.

Next, install the lower plastic cover. Insert the plastic fingers first by

sliding them under the front plastic cover just installed.

Install and tighten the lower cover plastic cover screws (one of the left and

one on the right). Be careful not to overtighten

these screws - they will crack the plastic cover if tightened too much.

My steering wheel would make a scraping sound when turning the wheel and I

found this to be caused by the horn contact - it was pressed too hard up

against the horn contact ring on the steering wheel. I pressed it down so that

it only lightly make contact when the wheel was fully

seated. Then I applied dielectric grease to the contact areas. No more scraping

sound!! ![]()

![]() Another

small victory!

Another

small victory!

Next comes the steering wheel. Since I left the

steering wheel perfectly centered when I took it off, I installed it the same

way.

Tighten the steering wheel nut. If you're fingers aren't long enough or small

enough to place the washer and start the nut, place the washer on a screwdriver

shaft and slide it down the shaft onto the end of the steering column. You can

use the same trick with the nut. I used my fingers. Tighten the nut with the

27mm socket to 36ftlbs while counterholding the

steering wheel or blocking the steering wheel so it doesn't move.

Connect the horn wire to the back of the horn pad....

...and position the horn pad over the steering wheel lining up the three clip

connectors. Then press down firmly over the top of each of the connectors until

you hear/feel the pad click/lock into place. Test the horn function.

Now you're done - go for a drive!

THANKS to the many others that have posted pictures and writeups

on this procedure before - I found them all most valuable and would have had a

much more difficult time takling this job (and

probably would have broke things along the way) if it weren't for those

documents and their authors.

I hope this helps some of the other noobies like

myself - feel free to comment or recommend improvements to the process. THANKS

for reading!