Rear Caliper Refurbish ('84)

Recently,

I was experiencing a scraping sound coming from the rear passenger side wheel

of the '84. I took the wheels off but could not see or hear the noise. Put the

wheels back on and there it was again. I feared something was wrong with the

emergency brake or brake pads. I had always planned to rebuild and clean up the

rear brakes since I went through the front suspension and brakes several months

ago so I figured now was as good a time as any.

I had never rebuilt the rear brakes before so I took a few pics

along the way to share with other Noobs like myself.

This post is long but hopefully others will find is helpful.

First, here's a list of the parts and tools I used for the job:

1. 11mm, 13mm, 14mm, 17mm, 19mm combination wrenches

2. 10mm, 19mm (or 3/4") sockets

3. 6mm allen socket (or allen

wrench)

4. Phillips screwdriver, Flat blade screwdriver

5. Regular pliers, spring clip pliers

6. Punch and small hammer

7. 2 small "C" clamps, 1 large 6" "C" clamp

8. Several quart size plastic baggies

9. Small pick

10. Micrometer

11. Painter's Tape

12. Caliper paint and clear coat

13. Silicone Lube and brake caliper grease

14. Brake cleaner

15. Disk Brake Quiet

16. Air compressor and vacuum pump

17. Brake Fluid

18. Set of Rear Brake Pads

19. 2 Rear Caliper Rebuild kits

20. 2 Rear Brake Rotors

21. 2 Rear Brake Hoses (I used stainless steel lines)

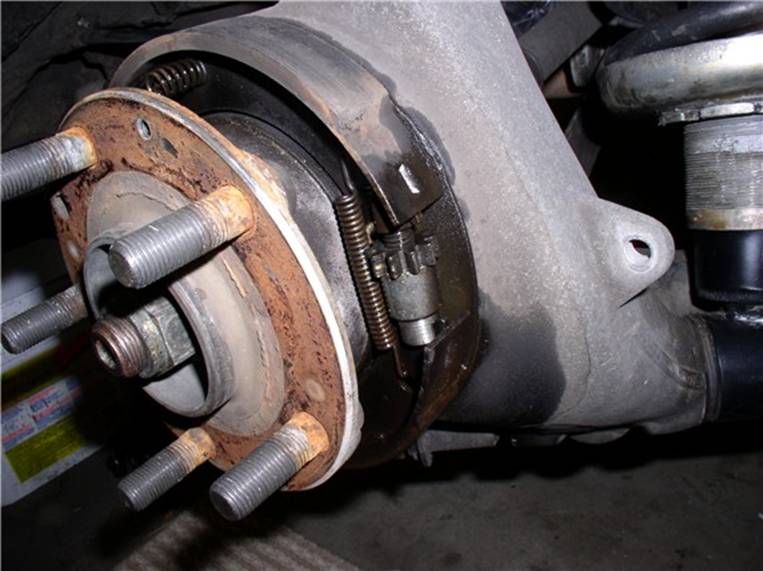

Start by blocking the front wheels, loosening the rear wheel lugs, lifting the

rear end of the car and supporting on suitable jack stands, and removing the

rear wheels. Here's where I start the disassembly

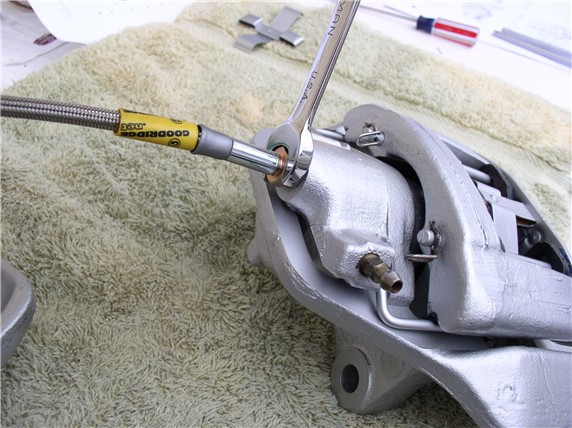

First, disconnect the brake line at the juction where

the steel brake line meets with the brake hose to the caliper. Get a bucket or

drain pan to catch dripping brake fluid. You will need the 11mm and 17mm

combination wrenches. Use the 17mm to counterhold the

large nut on the brake hose.

You can now remove the clip that secures the brake hose to the body. Use a flat

blade screwdriver to initially pry away the clip. If more help is needed, use

pliers to pull the clip out.

Now you can pull the brake hose away from the body mount.

Use a 14mm combination wrench to disconnect the brake hose from the caliper.

Next, use a

19mm (or 3/4") socket to take off the caliper bolts. There are two, one on

top and one on the bottom. I used a socket to the the

one on the top and a combo wrench to get to the one on the bottom because of

clearance.

At this point, you can remove the caliper from the rotor. However, the brake

pad sensor should still be attached.

To remove the brake pad sensor, you need to remove the sensor wire holder. Use

a pair of pliers to remove the 2 retaining pins and the holder will slide off

the retaining pins. Then, gently pull the wear sensor from the brake pad.

Now the caliper with pads should be free.

Set the caliper on a work surface and plug the brake line hole. I used a shop

paper towel.

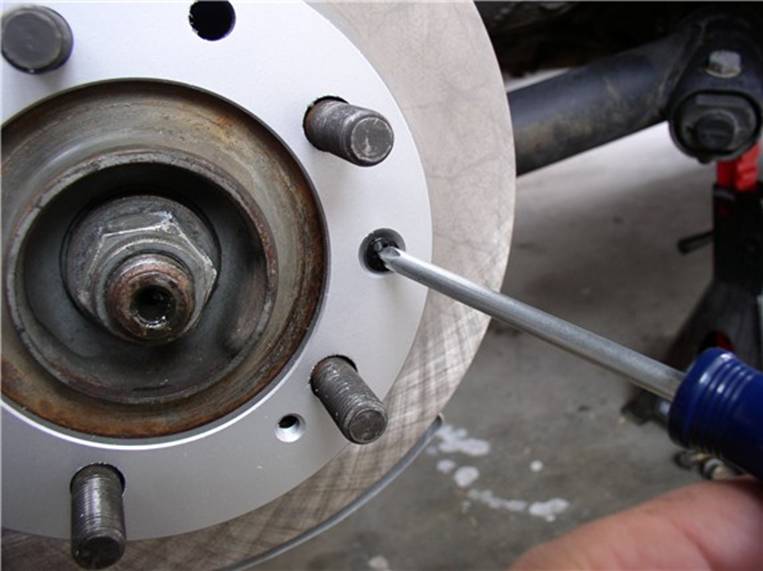

Next, you can take off the rotor. Use a large phillips screwdriver (or impact driver) to take the 2

screws out.

The rotor will come off after the 2 screws are out.

At this point, I discovered what was causing the scraping. A small pebble had

jammed between the rotor shield and rotor.

Now you can measure the thickness of the rotor with a micrometer. Mine turned

out to be about 19.7mm. New disk thickness is 20mm. Very little wear on my old

ones. Wear limit is 18.6mm.

Place a baggie over the exposed brake line to prevent dirt from getting on the

connection or inside the line.

Here's both calipers out and ready for disassembly.

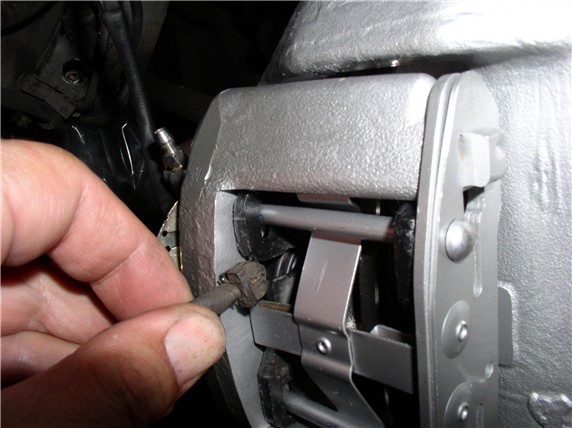

Next, remove

the pins that retain the pads in the caliper. I used a punch and small hammer

to lightly tap the end of the pin....

....then use a pair of pliers to grip the head of the pin and pull all the way

out.

After both pins are out and the retaining spring clip are

out, the pads will come out. Mine had disk brake quiet adhesive on them so it

took some light prying to get the pads out.

Next, separate the mounting frame (the piece that had the pins in it) from the

floating frame (the large flat piece) by pushing down on the mounting frame.

The guide spring is under tension so the frame will give some resistance. Don't

remove it completely.....

....I used a pair of small "C" clamps to hold the guide spring down

and his allowed me to safely and easily remove the

mounting frame.

Here's the mounting frame (right) and the floating frame (left) separated.

Now you can separate the cylinder from the floating frame. I used a large

"C" clamp (6") to press out the cylinder. I prefer this method

to the one cited in the WSM (i.e., hitting the cylinder with a plastic hammer).

All the parts have been disassembled from the frames.....

Next, you can focus on the cylinder disassembly. First, remove the clip that

holds the dust boot in place. The clip pliers I used here have been great. Made by Powerbuilt, sold a Kragen.

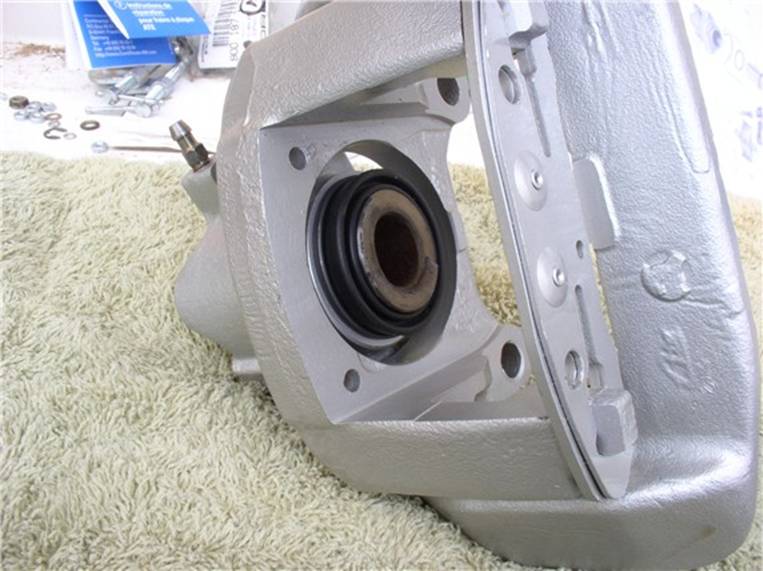

To remove the piston from the cylinder, I use a compressor. Before removing the

piston, make note of its orientation. According to the WSM, it should be

rotated about 20 degrees chamfer. Note the raised lip on the contact surface

that meets with the brake pad. I noticed one edge of the raised lip lined up

well with the bleeder fitting. Place the cylinder upside down (piston facing on

the ground) and use an inflator adaptor to fill the cylinder with compressed

air. It took between 40 and 60 PSI to press the piston out.

Once the piston is out, you can remove the dust boot and piston seal inside the

cylinder.

To remove the seal, I used a small pick to carefully get under the seal without

damaging the inside walls of the cylinder.....

....then pull out the seal.

Next, you can remove the frame slides (little plastic slides) attached to the

mounting frame. I used pliers to grip and rotate out. The caliper rebuild kit

comes with new ones.

I wiped down

the pistons and placed them in plastic baggies and labeled which cyliner each went with. I also marked the outside of the

cylinder with a scribe to match the piston label.

Back at the car, you can remove the rotor shield. It takes a 6mm allen bolt (3 of these) with a

13mm nut on the back side to counter hold. At the top of the shield there is a

single 10mm bolt to take out as well.

Once the bolts are out, the shield comes off.

I use brake cleaner to clean the dust and dirt off the emergency brake shoes,

springs, and adjustment wheel.

After the cleaning, inspect the shoes for wear or any other anomaly such as

broken springs.

Now the cleaning begins! Usually, I take the caliper parts to the machine shop

and have them clean/bead blast them. However, this time, I decided to give the

parts an acid bath. The acid bath works great and only takes about 5-10

minutes. Once the parts are finished with the bath, I towel dry them

immediately afterward.

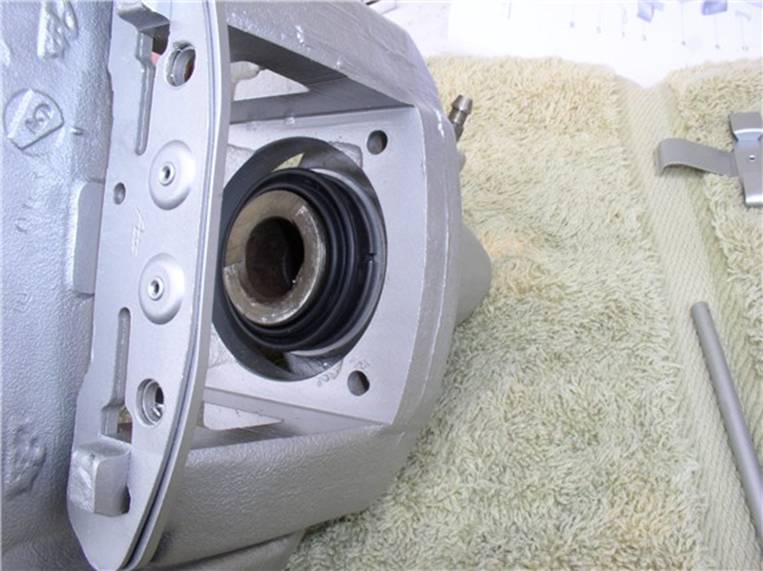

I used high temperature caliper paint and high temperature clear coat

(available at Kragen). I fashioned hangers from

clothes hangers to do the painting and hang for drying. I used a

silver/aluminum color and applied 3 coats of paint and 2 coats of clear coat. Here's the rotor shields and frames drying....

To paint the cylinders, I put the old brake hose back in the hole (since I had

new brake lines). If you are not replacing the brake lines, you can stuff the

brake line hose with a paper shop towel. Also, tape off the

cylinder opening and the bleeder fitting. Here's the cylinder drying....

I also painted the pins, slides and pad retaining clip. Here's

all the parts painted, dried and ready for reassembly.

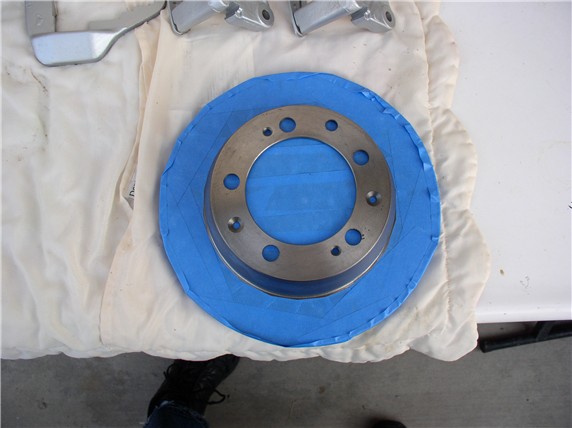

Next, I painted the rotor hats. First, use small pieces of painters tape to get

a near perfect circle around the base of the hat.....

....then apply painter's tape to the remaining parts of the rotor (including

the inside of the hat. Later you will use brake cleaner to remove any residue

from the disk surface.

You can simply place the rotors on a flat surface for painting. I used an old

piece of plywood.

Once the paint and clear coat have dried, remove the tape.

Next, you're ready to install the caliper rebuild kit. Here's the kit and all

the contents that come with it. It includes the dust boot, boot retaining clip,

frame slides, cylinder/piston seal. You should be able to get the kits from any

of the big 3. I used 928 Intl - fast, next day shipping at no extra cost - only

3 hours away!

To begin the

cylinder assembly, the WSM suggests using brake cylinder paste on the cylinder

walls, the piston and the seal (a very thin coat). I used silicone lubricant

and applied a VERY THIN coat.

First, apply the lubricant to the cylinder walls....

....then apply to the seal....

....and place the seal back into the groove in the cylinder.

Then put a very thin coat of lubricant on the piston outer surface.

Then position the piston according to the same orientation it came out. According to the WSM, about a 20 degree chamfer.

You should be able to press the piston in using both hands. But don't press it

in all the way. You still need to attach the dust boot. Leave enough room that

you can comfortably access the piston groove for the dust boot.

Next, according to the instructions in the caliper rebuild kit,

apply a very thin coat of lubricant to the inside of the dust boot.

Then place the dust boot (small opening) on the piston first....

....and pull the other end of the dust boot over the cylinder and on top of the

dust boot groove.

Next, install the dust boot retaining clip.

Make sure the clip is seated properly and up next to the cylinder edge.

Finally, check to make sure the dust boot is properly seated on the piston as

well.

Next, you can

assemble the cylinder onto the floating frame. First, place the guide spring in

the spring groove on the cylinder.

Now, position the cylinder on the floating frame by lining up the slots on the

cylinder with the notched frame edges.

Use the large "C" clamp to press the cylinder on the frame until you

encounter stiff resistance. Doing this will press the pistion

all the way into the cylinder. After the cylinder was seated in the floating

frame, I then use the compressed air to push out the piston slightly, just

enough so that the contact lip on the piston was protruding out from the dust

boot. I did not want the dust boot to make contact with the tacky surface of

the back of the brake pads.

Lubricate the end of the guide spring with brake caliper grease.

Install the plastic slides into the mounting frame.

Next, position the mounting frame inside the floating frame and position the

ends of the guide spring into their respective slots on the mounting frame. To

do this, you will need to spread the guide spring out in order to line up with

the slots.

After the guide spring is lined up with the mounting frame slots, you will need

to push down on the mounting frame while at the same time pushing in toward the

cylinder in order to line up the plastic guides with the notched edge of the

floating frame. Unfortunately, I did not have three hands to demonstrate....I

suppose I could have used the small "C" clamps again to hold down the

guide spring - but that didn't occur to me until just now!

When it's in place, it should look like this...

Next comes the brake pads. I use Disk Brake Quiet on

the backs of the pads. It's a tacky spray that eliminates pad squeak.

Just use one coat. Not too light of a coat and not too heavy either.

At this point,

it's a good idea to double check the orientation of the piston. This is the

last opportunity to make any adjustments if they are not at the proper

rotation.

According to the WSM, you can use piston pliers (don't know what those look

like) to rotate the piston, if needed. Mine looked OK.

Next, install the brake pads, I installed the outer

pad first. It has a slot in the back of the pad that lines up with and presses

into a rectangular notch on the floating frame. Be very careful to not touch

the pad surface if you have also touched the tacky brake quiet material. If you

need to press the pads in place, use a shop towel between the pad surface and

your fingers/gloves.

Place the inner pad (against the piston) next.

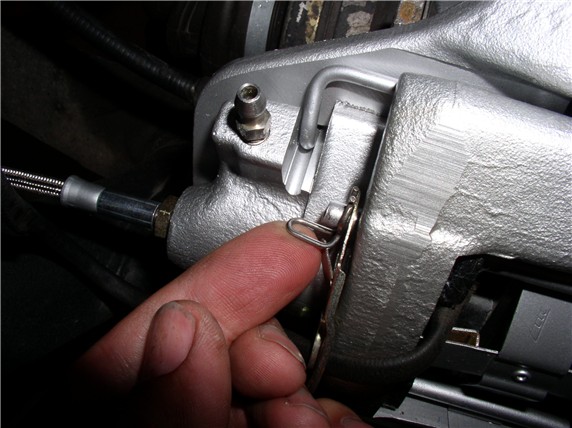

Now you can insert the retaining pins and clip. Start with one of the pins and

line it up with the holes in the mounting frame and the brake pads - push it

all the way through.

Next, install the spring retaining clip and second pin. Slide the wide end

under the first installed pin. You will need to press down on the other end of

the spring clip in order to get it under the second pin. Slide the second pin

in while holding down the spring clip.

Now install the new brake line. I'm using the stainless steel braided hose.

Connect the male end of the hose to the cylinder using the 13mm wrench and

tighten to 10 ftlb.

At this point, the caliper is ready to go back on to the car. Keep the plastic

cap on the other end of the line until ready to connect to the brake line.

Next, install

the rotor shield. These are fitted left and right so you can't mix them up.

Use the 6mm allen and 13mm

wrench to counter hold the 3 allen bolts. Also,

re-install and tighten the 10mm bolt at the top of the shield. I decided to be

adventurous and paint the heads of the bolts glossy black.

Install the rotors next. line up the phillips screw holes and press onto the wheel hub....

....and tighten the 2 phillips head screws. Also painted them black.

Before installing the caliper, clean the surface of the rotors with brake

cleaner and a shop towel. I belive a cloth towel

works better than the paper sort. Spray the cleaner directly on the towel and

wipe the surface (both sides) with the towel.

Next, install the caliper by tilting it into place and line up the holes for

the caliper bolts at hub carrier.

Next, install the caliper bolts using the 19mm (or 3/4") socket and combo

wrenches.

Install the brake pad wear sensor holding bracket. Feed the end of the sensor

through the holder and place the bracket on the mounting pins at the back of

the caliper - the same pins that hold the brake pads in place.

Connect the brake pad wear sensor to the brake pad. Be careful when insterting the plastic fitting into the brake as these can

be brittle and crack when forced. If it cracks and breaks, it will not stay in

place.

Install the wear sensor holding bracket locking pins.

Remove the plastic baggie on the end of the brake line and position the caliper

brake hose to match up with the steel brake line at the body bracket.

Connect the brake line with the female fitting on the caliper hose and hand tighten. Then, install the brake hose retaining clip on

the hose fitting and body mounting bracket. This will give the connection extra

resistance as you tighten the connection. Counterhold the brake hose with the 17mm wrench and tighten

the brake line nut with the 11mm wrench to 10 ftlb.

Install cable zip ties around the brake wear sensor wire and the caliper brake

hose. I used three zip ties on each wheel.

Add brake fluid to the reservior to make sure it's

full before bleeding the lines. You will need to check the level of the reservior frequently as you are bleeding the lines. I accidently let it get too low and ended up sucking air into

the lines.

Next, loosen

the bleeder fitting. If the bleeder is not clogged, you should see some fluid

slowly dripping out.

I used the vacuum pump approach to get the air out of the lines. This is the

first time I've used this approach, so it took some practice. A couple of

tricks I learned. First, air was being sucked through the threads of the

bleeder fitting. So I removed the fitting and put on some teflon tape. That fixed the problem. Second, be

careful how much fluid you suck out, I accidently

drained the reservior and saw lots of air bubbles

coming through! When tightening the bleeder fittings, they only need to be

tightened about 3 ftlb.

I did run into a plugged bleeder fitting and wondered how it got plugged. Then

I noticed that each of the fittings is supposed to have a protective cap on it

to prevent dirt from entering. All my caps are gone so I need to get some new

ones. In the meantime, if you have a clogged fitting, take it out and use a

small pick to clean the orifice. Make sure you can blow air through it before

putting it back in. Put the teflon

tape on the threads to ensure a good air tight fit for the vacuum pump.

Once the system is bled, top off the brake fluid reservior and check the rotation of the axle/brakes

for any anomalies. The wheels should rotate smoothly but firmly. Check the

operation of the emergency brake. Mine required no adjustment. I believe I read

in the WSM that the emergency brake should engage after about 2 clicks on the

e-brake handle. If yours is more than that, you may need to adjust the

adjusting wheel at the emergency brake shoes according the procedure in the

WSM.

Finally, mount the wheels to the car. I used optimoly

TA, the aluminum anti-sieze, on the mating surface of

the wheel.

Then mount the wheel, lower the car and take it for a test drive and listen for

unusual noises. Also, no hard braking for the first

50-100 miles so the brakes can bed in against the disks.

That's it!

I've tested mine and they seem to be doing just fine. Mark another job off the

list! Please feel free to comment or recommend any improvements to this process

as I'm learning along the way.

My wife and I

took both the sharks out for our favorite run late this afternoon - I'm in the

lead and she's right behind. I noticed a little vibration at triple digits so

slowed down pulled over and checked temp of wheels. One of the rear (driver's side) was hot. Drove conservatively home and

checked the wheel. Sure enough, the emergency brake shoes were just a little

tight. I backed them off a few notches (of the adjusting wheel) and spun the

wheel - much better. Took it for another speed run. PERFECT - barely warm now. Please make sure the emergency

brake pads are not too snug - wheels should spin (off the ground) with no

noticeable resistance (pulsing). I thought I caught this on reassembly but must

have missed it!

THANKS for

reading!